The internet is currently enamored with a viral photo series of police puppies trying their very best to look intimidating—and failing adorably. Inspired by a trending article on law enforcement K‑9 units, these images showcase German Shepherds, Belgian Malinois, and other future service dogs in training, all being meticulously conditioned for discipline, responsiveness, and absolute reliability under pressure.

Beneath the cuteness lies a serious truth: behind every competent police dog stands a regime of uncompromising training, routine checks, and methodical care. That same philosophy, translated to your vehicle, is the foundation of truly elite brake maintenance. Just as a K‑9 handler cannot afford a moment of hesitation from their partner, a discerning driver cannot afford uncertainty from their braking system—especially in fast‑changing traffic and weather conditions.

Below are five exclusive, K‑9‑inspired insights for motorists who see brake safety not as a basic requirement, but as a refined standard of performance.

The Discipline of Routine: Why “Feel” Is Not a Maintenance Plan

K‑9 units follow strict training schedules; they do not wait for a “bad day” to adjust behavior. In contrast, many drivers wait until the brake pedal feels “a little off” or a warning light appears before investigating. For a premium standard of safety, your brakes deserve a regimen, not a reaction.

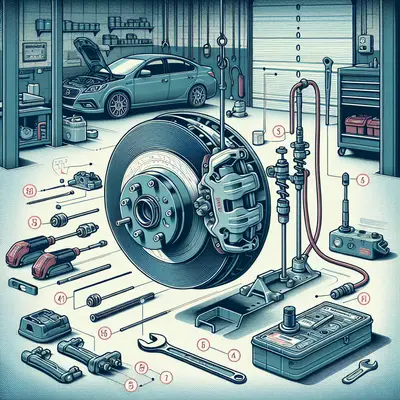

Establish a defined inspection cadence, independent of obvious symptoms. A high‑integrity schedule for daily‑driven vehicles is a professional brake inspection roughly every 10,000–12,000 miles, or at least once a year—whichever comes first. This is not merely about pad thickness; it is about ensuring a cohesive system: pedal feel, fluid condition, hose integrity, rotor surfaces, caliper slide freedom, and hardware condition. Like the quiet daily drills of a police dog that the public never sees, the best brake maintenance is often invisible—but always deliberate.

Precision Under Pressure: Treat Brake Fluid Like a Mission‑Critical Asset

In law enforcement, a K‑9’s ability to perform under extreme stress is everything. The parallel in your braking system is your brake fluid. It is not simply a fluid; it is the medium transmitting your intent to stop into mechanical reality. Over time, brake fluid absorbs moisture, lowering its boiling point and compromising performance under hard or prolonged braking—particularly during spirited driving, mountain descents, or hot summer traffic.

Discerning owners should treat fluid changes as a precision service, not an afterthought. For most vehicles, a complete brake fluid exchange every two to three years is a refined standard, regardless of mileage. Insist on the correct specification (DOT 3, 4, or 5.1, as specified by the manufacturer) and ask your shop whether they test the fluid’s boiling point or moisture content, rather than relying solely on age. A truly premium approach includes:

- A full system flush, not just a top‑off

- Clean, sealed fluid containers (never open jugs sitting on a shelf)

- Proper bleeding sequence to avoid trapped air

Just as a K‑9 unit cannot compromise responsiveness when a situation escalates, your fluid cannot be allowed to fade when you need maximum stopping power most.

The Art of Symmetry: Matching Components for Predictable, Confident Stops

K‑9 handlers understand balance: training, rest, diet, and workload must be harmonized for reliability. In brake maintenance, that same balance means preserving symmetry across the axle and system. Mixing radically different pad compounds or rotor qualities side‑to‑side or front‑to‑rear can create unpredictable braking characteristics—subtle at low speed, unsettling in an emergency.

For a refined standard of maintenance:

- Always replace pads and rotors in axle sets (both front or both rear), not singly

- Avoid combining ultra‑aggressive pads on the front with bargain, low‑bite pads on the rear; aim for matched behavior, not simply matched prices

- Ensure calipers on the same axle are performing identically—sluggish slide pins or a sticky piston on one side can cause the vehicle to pull under braking

Elite braking is not only about stopping quickly; it is about stopping straight, predictably, and without drama. That calm, composed deceleration is the result of symmetry—just as the most impressive K‑9 demonstrations appear effortless because everything behind the scenes is in equilibrium.

Surface Intelligence: Reading Rotors the Way Trainers Read Body Language

Experienced K‑9 handlers learn to read subtle shifts in posture, breathing, and focus. In much the same way, a truly careful brake inspection treats rotors as a “report card” for the entire system. Premium maintenance goes beyond measuring thickness and checking for obvious grooves; it interprets what the rotor’s surface is trying to say.

A sophisticated rotor evaluation includes:

- **Pad deposition patterns:** Uneven, patchy transfer layers can indicate improper bedding, seized caliper hardware, or mismatched friction materials.

- **Heat signatures:** Bluish discoloration, localized hot spots, or visible micro‑cracks suggest overheating or dragging pads.

- **Runout and thickness variation:** Slight disc thickness variation (DTV) can create steering wheel vibration and is often the result of improper wheel torque, contaminated hub surfaces, or neglected hardware.

Instead of simply machining or replacing rotors on principle, ask your technician what the old surfaces revealed. A premium approach treats every rotor as data, allowing you to correct underlying issues before they compromise your next set of components—echoing how K‑9 trainers refine their program by observing every session, not merely the failures.

Environmental Conditioning: Preparing Your Brakes for “Real‑World Duty”

K‑9s are not trained exclusively in quiet, empty fields; they are conditioned to perform amidst sirens, crowds, adverse weather, and unpredictable distractions. Your brakes, too, must be prepared for the environment in which they actually serve—not an idealized, laboratory version of driving.

Elevate your maintenance by considering:

- **Climate:** In regions with heavy road salt, insist on regular cleaning of caliper slides, pad ears, and backing plates, and consider upgraded anti‑corrosion hardware. In hot climates, prioritize premium fluids and pads rated for higher temperatures.

- **Driving profile:** City commuters with frequent stop‑and‑go driving may need pads, rotors, and fluid serviced more frequently than highway‑dominant vehicles, even with similar mileage.

- **Load and duty:** If you tow, carry heavy cargo, or frequently drive mountain passes, upgrading to higher‑friction, fade‑resistant pads and rotors designed for higher thermal loads is a mark of thoughtful ownership.

Finally, just as K‑9 units perform scenario‑based training, you should occasionally test your brakes in a controlled, safe environment—a firm stop from moderate speed on an empty road—to assess pedal consistency, noise, and vehicle behavior. That quiet, intentional “drill” can reveal concerns long before an emergency does.

Conclusion

The current fascination with police puppies trying—and adorably failing—to look menacing is a charming reminder that behind every capable K‑9 unit lies disciplined, meticulous care. The same is true of your braking system. Elite stopping power is not an accident; it is the result of deliberate routine, precision fluid management, component symmetry, intelligent rotor analysis, and environment‑aware preparation.

For the discerning motorist, brake maintenance is more than checking a box on a service sheet. It is a curated practice that ensures every journey—whether a daily commute or a long‑distance drive—unfolds with the quiet confidence of equipment that has been trained, tested, and trusted to perform when it matters most.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.