When a photo of a crosswalk painted neatly around a parked car goes viral, it’s amusing. When a contractor installs a door that can’t open because of a stair rail, we laugh, share, and move on. That’s the charm of the “Not My Job” trend currently sweeping social media—highlighted again this week in Bored Panda’s roundup of “People Are Sharing Priceless ‘Not My Job’ Moments.” It’s a global gallery of work technically “done,” but done without care, context, or accountability.

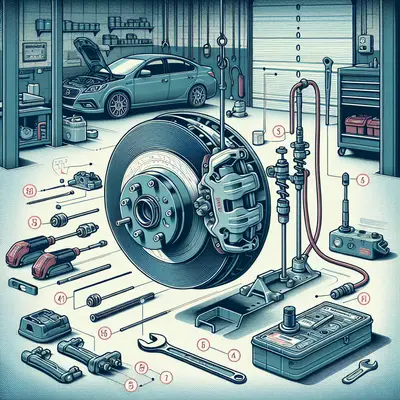

On a city sidewalk, that kind of negligence makes for a meme. Inside a braking system, it becomes something far more serious. Brakes are the last place where “good enough” or “I did my part” should ever be acceptable. And yet, many vehicles on the road today quietly reflect the same mindset: pads installed without cleaning hardware, rotors replaced without proper bedding, fluid “topped up” instead of replaced, and torque specs treated as mere suggestions.

For discerning drivers who view safety and refinement as non‑negotiable, this cultural moment is a sharp reminder: in brake maintenance, every detail is someone’s job—and ultimately, it’s yours to insist that it’s done properly. Below are five exclusive, high‑standards insights inspired by the “Not My Job” phenomenon, tailored for those who expect their brakes to perform as impeccably as their car looks and feels.

1. The Hidden Cost of “Half‑Done”: Why Brake Jobs Must Be Systemic, Not Isolated

Many of the most-shared “Not My Job” photos show work that is technically complete, but contextually wrong—a fence built around a tree, a painted line that respects the cone more than the road. The same thing happens in braking systems when shops sell “pad-only” services. The pads are new, the invoice looks tidy, but the system has not truly been serviced.

A premium brake service should treat the system as an interdependent whole. That means evaluating and, when appropriate, refinishing or replacing rotors instead of merely resurfacing them beyond spec. It also means inspecting caliper slide pins for freedom of movement, ensuring pistons retract smoothly, and checking rubber boots and seals for age-related cracking. Anti-rattle clips and pad shims should be cleaned or renewed, not simply re-used in whatever condition they arrive in. If you receive an estimate that focuses almost exclusively on pads, with no mention of hardware, rotor condition, or hydraulic health, you are seeing the brake equivalent of that infamous misaligned crosswalk: work done in isolation, not in context.

For a vehicle you trust at highway speeds, “partial” is not protection—it’s theater. Insist on system-level maintenance, not isolated component swaps.

2. Torque as a Craft, Not a Guess: The Art of Even Clamping

In those viral “Not My Job” images, misalignment is everything: a handrail that doesn’t meet the stairs, a sign mounted backward, a tile pattern that breaks at the edge. Misalignment in braking isn’t humorous; it shows up as vibration, uneven wear, or—more insidiously—reduced emergency stopping capability. The most overlooked contributor? Improper torque.

Every wheel lug nut, caliper bracket bolt, and caliper guide pin has a specified torque value, determined not only for safety but for uniform clamping. When lug nuts are hammered on with an impact gun and no torque wrench, the resulting uneven clamping can cause rotors to distort under heat cycles. That distortion may be imperceptible at first, but it can reveal itself later as steering wheel shake, pulsing under braking, or premature rotor replacement.

For a truly refined braking experience, torque needs to be treated like fine watchmaking: deliberate, measured, and repeatable. Ask your shop whether they use calibrated torque wrenches and follow manufacturer specifications—not “feel,” not “we’ve always done it this way.” If you change wheels seasonally or swap between summer and winter setups, make torque verification part of that ritual. The difference in pedal feel and long-term rotor health is tangible.

3. Cleanliness as Performance: Why Surface Prep Separates Ordinary from Exceptional

Many “Not My Job” photos share another theme: someone did the minimum visible work and ignored what sits underneath. Old signs left behind the new one, unremoved tape under fresh paint, debris sealed beneath tile. Brakes are equally unforgiving when it comes to what lies beneath the visible components.

Premium brake maintenance treats cleanliness and surface preparation as performance work, not cosmetic fussiness. Before installing new pads and rotors, the hub face should be meticulously cleaned of rust, scale, and old corrosion products; a rotor that doesn’t sit perfectly flat on the hub will never run true. Pad abutment surfaces should be cleaned back to bare metal before fresh high‑temperature brake lubricant is applied—never smeared over contaminated surfaces. Caliper pistons must be gently pushed back with care taken not to damage seals, and external dirt should be removed before they are retracted to avoid dragging contamination past critical sealing surfaces.

This is the difference between brakes that merely function and brakes that feel silk‑smooth, linear, and confidence‑inspiring for tens of thousands of miles. When reviewing an estimate, don’t be shy about asking what surface preparation steps are included. “Remove and replace” should always be accompanied by “clean, inspect, prepare.”

4. Fluid Is Not a Decoration: Why “Topping Up” Is a Red Flag

One of the quietest “Not My Job” habits in the industry is the brake fluid top‑off. The reservoir is low, someone pours more fluid in, the level looks right, and the box is checked. In the world of viral memes, that’s like placing a sticker over a crack in the wall and calling it “renovated.” The appearance has changed; the underlying reality has not.

Brake fluid is hygroscopic—it absorbs moisture over time. That moisture lowers the boiling point of the fluid and accelerates internal corrosion in master cylinders, calipers, and ABS components. Once contaminated, brake fluid cannot be “fixed” by topping up; the entire system needs to be flushed with fresh fluid until it runs clear and meets specification. For most vehicles, a two- to three-year interval is a prudent cadence, particularly for those driven spiritedly, frequently loaded, or in challenging climates.

If your service invoice mentions “brake fluid top‑off,” treat that as a conversation starter. Ask when the fluid was last flushed and whether the shop uses test strips or boiling point testers to assess fluid condition. A complete, properly performed brake fluid exchange is one of the most cost‑effective ways to protect both safety and the longevity of high‑value components.

5. Documentation as a Safety Luxury: How to Build a Brake Maintenance Dossier

The viral “Not My Job” images resonate because they show tasks done with no eye on the future—no thought for who will use that sidewalk, that doorway, that sign. A premium approach to brake care does the opposite: it looks forward, and it documents. For owners who treat their vehicles as long‑term companions or high‑value assets, this is where maintenance becomes a form of quiet luxury.

Instead of relying on memory or sparse invoices, consider building a dedicated brake maintenance dossier for your car. Record pad brands and friction grades, rotor type and manufacturer, torque specs used, fluid brand and DOT rating, and the dates and mileage at each service. Note any bedding‑in procedures followed and any transient noises or sensations that appeared afterward and later disappeared. Over time, you’ll build a nuanced performance and reliability history tailored to your specific vehicle and driving style.

This level of documentation offers three advantages. First, it helps you make evidence‑based decisions about upgrade paths—whether to move to higher‑temperature pads, slotted rotors, or stainless lines. Second, it equips you to hold service providers to a higher standard, as you know what has been done and what has merely been billed. Third, if you ever sell the vehicle, a well‑kept maintenance dossier signals to a discerning buyer that this car was not merely driven, but curated.

Conclusion

The internet will keep serving us “Not My Job” moments—crooked signs, misaligned tiles, and paint jobs that honor the cone more than the road. They’re entertaining precisely because none of them carries life‑and‑death consequence. Your brakes are different. In that closed world behind each wheel, there is no room for “good enough,” no tolerance for shortcuts masked as efficiency.

Elite brake maintenance is not about extravagance; it is about respect—for engineering, for physics, and for the people you protect every time you press the pedal. Insist that each task has a rightful owner, that every detail is someone’s job. When you treat your braking system with that level of seriousness, you move beyond basic safety into something rarer: the quiet confidence that your car will respond exactly as you expect, precisely when you need it most.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.