Typography Twitter has been having a moment. A trending Bored Panda feature, “People Are Sharing Design Examples That Show How Important Proper Spacing Really Is,” has designers and casual readers alike wincing at poorly spaced signs, chaotic menus, and unintentionally hilarious billboards. The takeaway is obvious: small details, when neglected, can completely distort meaning.

For discerning drivers, this viral conversation about spacing and precision should feel familiar. The same microscopic misjudgments that ruin graphic design can quietly undermine your braking system. A few millimeters in the wrong direction can transform a poised, confident stop into a vague, unsafe guess.

Today, while the internet laughs at badly spaced shopfronts, it’s worth asking a more serious question: if such tiny errors can wreck a logo, what happens when we allow similar tolerances to slip on our brakes?

Below are five exclusive, detail‑driven insights for motorists who treat stopping power as a non‑negotiable luxury, not an afterthought.

The Hidden Geometry of Brakes: Why “Spacing” Is Your Silent Bodyguard

In typography, spacing governs legibility. In braking, spacing governs survival. Every component in your brake system is defined by gaps and clearances measured in fractions of a millimeter: pad to rotor, rotor to caliper, fluid volume to piston travel. When these relationships drift, performance fades—subtly at first, then suddenly, under stress.

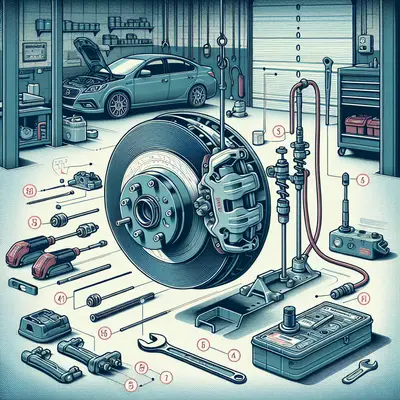

Excessive pad-to-rotor clearance forces your pedal to travel farther before anything meaningful happens; the result is a soft, indistinct response that robs you of confidence. Uneven rotor thickness—known as DTV (Disc Thickness Variation)—creates microscopic “high spots” that push the pads back each rotation, producing pedal pulsation and longer stopping distances. Even caliper slide pins that are lightly corroded can slow pad retraction, causing drag, heat, and premature wear. Luxury‑level braking is not about “good enough”; it is about restoring and preserving the intended geometry of the system, the way a meticulous designer respects the grid behind a flawless layout.

Precision Over Guesswork: Why Visual Checks Are No Longer Enough

Social feeds today are full of armchair design critiques—people spotting bad kerning from a single photo. Yet, when it comes to brakes, many motorists still rely on a quick glance through the wheel spokes and call it an inspection. That visual check is equivalent to judging a sophisticated book layout from its cover thumbnail alone.

A premium maintenance approach embraces instrumentation. Rotor thickness should be measured with a micrometer across multiple points, not “eyeballed” for grooves. Runout—the subtle wobble of a rotor as it spins—must be checked with a dial indicator, not inferred from a vague vibration report. Brake fluid quality should be tested for moisture content, not simply looked at for color. The era of casual inspection is over; modern vehicles, especially those with advanced driver‑assistance systems, demand the same level of quantifiable precision you’d expect from a high‑end watchmaker. If your technician isn’t measuring, they’re guessing—and precision braking has no room for guesswork.

Thermal Discipline: Curating Heat Like a High‑End Material

Bad spacing in design scatters attention; bad heat management in brakes scatters performance. Viral conversations around design might seem worlds away from stop‑and‑go traffic, yet both disciplines revolve around control. Heat is the invisible currency of every stop—kinetic energy transformed into thermal load at your wheels—and refined maintenance treats it with the same respect a luxury tailor gives to delicate fabrics.

Rotors that are too thin (even if they “look fine”) shed mass, reducing their ability to absorb and dissipate heat; once below minimum thickness, they can overheat, warp, or crack under hard braking. Inferior pad compounds may perform acceptably on a cool suburban commute, then fade dramatically on a steep downhill run or during repeated highway stops. Calipers with partially seized pistons keep pads dragging, turning gentle city driving into an unintended stress test, cooking fluid and glazing surfaces. An elite strategy doesn’t just replace worn parts—it curates components and conditions to keep heat within a controlled, predictable range, preserving both feel and fade resistance when you most need them.

The Luxury of Silence: Interpreting the Subtle Language of Brake Noise

The internet loves the obvious disasters: signs whose mis‑spaced letters spell something unintentionally offensive, menus you need a decoder ring to read. But in braking, the most important messages are rarely that loud. They arrive as whispers—faint squeaks, a soft chirp at low speeds, the briefest grind when backing out of the driveway.

These sounds are not mere annoyances; they’re signals, like misaligned text on a premium product box. A high‑pitched squeal under light application can indicate pad glazing, insufficient lubrication on contact points, or cheap pad formulations that trade refinement for low cost. A rhythmic scrape that comes and goes with wheel speed may suggest minor rotor scoring or a dust shield brushing under load—both small issues that can evolve into larger ones. Even silence itself can be suspicious: a brake system that suddenly becomes quieter after months of noise may have worn through its pad wear indicators and is now running dangerously low on friction material. The refined driver doesn’t wait for catastrophic grinding; they respond to early, subtle cues and treat their brakes as a finely tuned instrument, not a blunt tool.

Calibrated Confidence: Aligning Modern Tech With Impeccable Basics

As Bored Panda’s design feature reminds us, sophisticated outcomes rely on humble fundamentals—proper spacing, thoughtful structure, disciplined execution. Your vehicle’s advanced technology is no different. ABS, stability control, automatic emergency braking, and adaptive cruise systems are calibrated around an assumption: that your mechanical braking fundamentals are intact and within specification.

Worn pads, tapered wear, uneven rotors, or degraded fluid shift those underlying assumptions. The car’s algorithms will still attempt to compensate, but their responses become less predictable and less repeatable. That extra half‑second of delay or extra few feet of stopping distance may never matter in routine driving—but in a genuine emergency, they define the line between a controlled near‑miss and an avoidable impact. Premium maintenance goes beyond “passing inspection.” It means aligning the hardware—pads, rotors, calipers, hoses, fluid—with the software sophistication layered on top, so your safety systems perform at their engineered peak, not at a compromised approximation.

Conclusion

The internet’s fascination with badly spaced signs is more than a shared joke; it’s a reminder that detail is destiny. If a few misplaced millimeters can turn a simple storefront into a viral cautionary tale, imagine the stakes when those millimeters live inside your braking system.

For the discerning motorist, truly luxurious driving is not measured in leather stitching or ambient lighting, but in the calm, unwavering assurance that when you ask your vehicle to stop, it does so with composure and authority. That confidence is crafted—not by chance, not by minimum‑standard servicing, but by a meticulous, measurement‑driven approach to brake maintenance.

In a world captivated by design errors, choose to be the exception on the road: understated, impeccably maintained, and prepared for the moments when precision is no longer a preference, but a necessity.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.