We’ve all seen them: those viral design disasters where a single misplaced space turns a serious message into an accidental joke. A trending piece today on Bored Panda highlights “People Sharing Design Examples That Show How Important Proper Spacing Really Is” — an entertaining reminder that tiny details can completely alter meaning. In graphic design, poor spacing makes a sign unreadable. In your vehicle, the “spacing” inside a brake system is far more consequential: a few millimeters can separate a confident, controlled stop from a terrifying near‑miss.

While the internet laughs at bungled kerning and clumsy layouts, discerning drivers can draw a more serious lesson. Just as professional typographers obsess over alignment, spacing, and legibility, truly elite brake maintenance is about respecting the invisible tolerances, clearances, and calibrations that most people never see. Today, as those design missteps trend across social media, it’s the perfect moment to look at how “spacing” failures inside your braking system quietly accumulate—and how to prevent them with the same precision a luxury brand might apply to its flagship sedan.

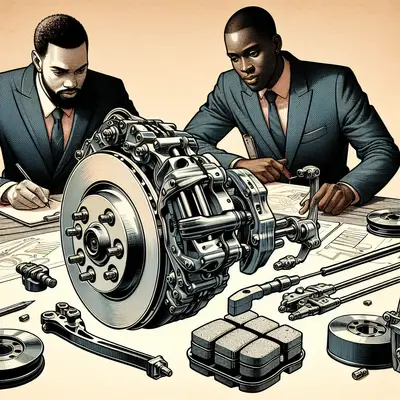

Below are five refined, often-overlooked insights for motorists who view brake safety not as a chore, but as a cornerstone of a premium driving experience.

1. The Silent Geometry of Brake Pad–Rotor Spacing

Behind every smooth, drama‑free stop lies a carefully controlled gap between the brake pad and the rotor. This clearance is measured in fractions of a millimeter, yet it governs pedal feel, response time, and noise. When new, high‑quality pads and rotors are designed to sit perfectly parallel, with uniform contact across the rotor face. Over time, heat cycles, corrosion, and uneven torque on wheel lugs can subtly distort that geometry.

The result feels a lot like bad text spacing: the pedal may feel “patchy,” with a faint pulse or subtle vibration, or you may sense an inconsistent bite as you slow from highway speeds. Many drivers ignore this until the steering wheel shakes violently during braking, but by then rotor thickness variation and pad taper are well advanced. Elite maintenance means addressing micro‑symptoms early: a whisper of pedal flutter, a faint rhythmic squeak, or a slight pull to one side. A skilled technician will measure rotor run‑out, check pad wear patterns, and ensure caliper slides are moving freely so that pad‑to‑rotor spacing remains uniform. Think of it as kerning for your stopping power: precise, deliberate, and meticulously aligned.

2. Fluid Pathways: The “Line Spacing” That Protects Your Pedal

In the viral design examples, too little line spacing crushes text into an unreadable block; too much makes it hard to follow the message. Your brake lines and internal hydraulic passages are subject to a similar law: they must remain impeccably clear and correctly filled to transmit your foot’s pressure into reliable stopping force. Over years, brake fluid slowly absorbs moisture from the air through rubber hoses and seals. That water doesn’t just lower boiling resistance; it also encourages internal corrosion, which can begin to constrict the “pathways” inside lines, calipers, and ABS components.

The first hint is often a brake pedal that feels slightly spongy or requires more travel before the vehicle begins to decelerate decisively. Elite service intervals replace brake fluid not “when it looks dark,” but at disciplined mileage or time thresholds—typically every two to three years, regardless of appearance. A premium‑minded owner insists on fluid that meets or exceeds the vehicle’s exact DOT specification and avoids mixing incompatible types. Much like a luxury publisher won’t tolerate ink bleed or clogged type, you should never accept murky fluid or unknown service history. When the hydraulic “spacing” inside your system is clear and uncompromised, your pedal becomes what it should be: a crisp, confident extension of your intent.

3. Torque, Tolerances, and the Art of Even Pressure

The Bored Panda piece illustrates how a single misaligned word can throw off the elegance of an entire design. Wheels are similar: one poorly torqued lug nut can distort an otherwise perfectly engineered brake system. Over‑tightening (or uneven tightening) with an impact gun is a quiet enemy of refined braking. It introduces rotor warpage, hub distortion, and micro‑movement between mating surfaces, all of which degrade the car’s ability to apply braking force smoothly and symmetrically.

Discerning owners should insist that wheels be tightened with a calibrated torque wrench, and that lug nuts be fastened in the proper star pattern to ensure even clamping force. This is standard practice in high‑end performance garages for good reason: it preserves rotor flatness and long‑term brake comfort. If you’ve ever noted that your car feels perfectly balanced at speed, yet develops a shudder only when you brake, improper torque is a prime suspect. Correcting it is not a glamorous upgrade, but it’s a hallmark of truly premium care—the kind that respects tolerances at the same granular level that a watchmaker respects the fit of each gear.

4. Pad Compound “Character”: Matching Feel to Your Driving Style

In typography, not all fonts are equal; a luxury brand would never choose a clumsy, informal typeface for a flagship campaign. Likewise, not all brake pads are created for the same kind of driver. Modern automakers—from European luxury marques to performance‑oriented Japanese brands—tune pad compounds to strike a specific balance between bite, noise, dust, and rotor wear. Replacing them haphazardly with a “one‑size‑fits‑all” aftermarket pad can degrade not just safety, but the subtle personality of your car’s braking behavior.

A premium approach considers how and where you drive. Urban commuters may prefer a pad with strong cold bite and low noise, while spirited drivers on mountain roads might prioritize fade resistance and consistent performance at higher temperatures. Advanced ceramic compounds can offer refined pedal feel and quiet operation, but some formulations trade away initial aggressiveness. An expert technician—or a well‑chosen specialist shop—can recommend pads that maintain or elevate your vehicle’s original braking “signature.” The goal isn’t simply to stop; it’s to preserve the composed, reassuring demeanor of a well‑engineered chassis, turn after turn, stop after stop.

5. Reading Wear Patterns Like a Fine Print Critique

The viral design examples are entertaining because mistakes are visible to everyone. Inside your brake system, however, the “bad design” accumulates mostly out of sight. That’s why elite maintenance treats each brake inspection as a kind of forensic reading of the system’s history. Pad wear that’s heavier on the leading edge, for example, can point to caliper guide pin issues or improper lubrication. Grooves on one section of a rotor might suggest a seized piston or contamination from road debris. Uneven rear brake wear relative to the front can highlight a malfunctioning proportioning valve or electronic brake distribution system.

Most quick‑service inspections glance only at remaining pad thickness. A discerning owner asks for more: photos of each corner, notes on wear patterns, rotor thickness measurements, and an explanation of any asymmetries. This level of insight transforms brake service from a reactive expense into a predictive, preventative practice. You’re no longer waiting for a squeal or warning light; you’re interpreting quiet signals, the way a seasoned editor sees problems in a layout long before the public ever does.

Conclusion

Today’s viral fascination with botched spacing and clumsy typography is more than a social‑media distraction—it’s a reminder that details dictate outcomes. In design, imprecise spacing creates confusion and unintended humor. In braking, it creates risk. For those who regard driving as a refined experience rather than a mere necessity, brake care deserves the same meticulous attention a luxury publisher gives to every page: correct spacing, aligned geometry, consistent character, and deep understanding of underlying structure.

By attending to the invisible clearances, fluid pathways, torque tolerances, compound selections, and wear patterns within your brake system, you elevate safety from a checkbox to a craft. Your reward is not just shorter stopping distances, but a quieter mind every time traffic compresses unexpectedly ahead—a subtle, premium assurance that when it’s time to stop, your car will do so with the same elegance and precision with which it was built.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Brake Systems.