Even the most advanced vehicle is only as reassuring as its ability to stop—quietly, predictably, and without drama. For drivers who value composure and control, brake maintenance is not an occasional inconvenience; it is a disciplined habit. Beyond the obvious pad changes and fluid top‑ups lies a more refined level of attention, where small, informed decisions translate into meaningful safety and long-term confidence at the wheel.

This guide explores brake maintenance as a quiet discipline rather than a reactive repair, with five exclusive, detail-focused insights that safety‑conscious owners rarely hear in standard service conversations.

Understanding Brake Wear as a Pattern, Not an Event

Most drivers think of brake wear as a single moment of failure—pads “worn out,” rotors “warped,” fluid “low.” In reality, brake systems leave a trail of subtle clues long before any warning light appears. Paying attention to patterns transforms maintenance from guesswork into informed stewardship.

Listen for changes in sound over time, not just obvious squeals. A soft, intermittent scrape under light braking that disappears under hard braking, for instance, can indicate early rotor surface inconsistencies or minor debris caught between pad and disc. Slight differences in steering feel under braking—such as a faint tug to one side that wasn’t there a month ago—can hint at caliper slide pin issues or uneven pad contact.

A safety‑first driver benefits from tracking these changes. Note dates and mileages when you first notice new sensations: faint vibrations, altered pedal travel, or longer stopping feel on familiar roads. This informal “brake log” becomes a powerful tool when speaking with a technician, helping them pinpoint issues earlier and avoid unnecessary or misdirected repairs. In a refined maintenance approach, you are not waiting for problems to announce themselves loudly—you are learning the language of subtle change.

The Often-Ignored Role of Brake Fluid Health

Brake fluid is the quiet ambassador of your stopping power. It never appears on the dashboard, and yet its condition dictates how consistently your brakes respond under stress. Modern vehicles generally recommend fluid changes every 2–3 years, but serious, safety-conscious owners treat this as a firm discipline, not a flexible guideline.

Brake fluid is hygroscopic—it absorbs moisture from the air over time. That moisture lowers the fluid’s boiling point and can allow internal corrosion of lines, calipers, and ABS components. The result may not be a dramatic failure; instead, it shows up as a vague, spongy pedal during repeated stops, especially on long downhill stretches or in spirited driving. The car still stops, but with less definition and authority.

An elevated maintenance standard includes periodic testing of brake fluid for moisture content or boiling point rather than simply relying on age or mileage alone. Many shops now use electronic testers or boiling point devices to quantify fluid health. For drivers who tow, live in humid climates, or drive in mountainous areas, a more frequent brake fluid service schedule is a subtle yet critical layer of safety. Fresh, high-quality fluid does not just protect components; it preserves the crispness and predictability of the brake pedal under the situations that matter most.

Exclusive Insight 1: The “First-Stop” Check After Every Service

One refined habit separates meticulous owners from casual drivers: the deliberate “first-stop” check after any brake-related service. Instead of simply driving away from the workshop and rejoining traffic, treat the first few hundred yards as a private safety audit.

Choose a quiet, low-speed area—as soon as you leave the facility, perform several gradual but firm stops from 20–25 mph. You are not testing stopping distance at high speed; you are assessing character: pedal height, firmness, noise, and the car’s directional stability under braking. Does the pedal feel higher or lower than before? Is there a new vibration, a faint grind, or a pull that did not exist on the way in? Is the ABS behavior consistent if you carefully trigger it on a low‑grip surface?

This deliberate, controlled verification gives you immediate awareness of any abnormality while you are still close to the service center, where adjustments or corrections are simplest. It is a habit that takes less than two minutes yet can prevent you from discovering a serious issue for the first time at highway speed. For the safety‑first driver, a first-stop check is not optional formality; it is a personal assurance ritual.

Exclusive Insight 2: Matching Brake Pad Character to Your Driving Style

Not all brake pads are created with the same personality. Many owners simply accept whatever pad a workshop installs, but discerning drivers understand that pad selection subtly shapes the car’s braking behavior, noise, and dust levels—each with safety implications.

Organic, semi‑metallic, and ceramic pads each have different friction profiles, temperature tolerances, and noise characteristics. For example, premium ceramic pads often provide quieter operation and lower dust, but some formulations can offer a different initial “bite” compared with semi‑metallic compounds. For urban, stop-and-go driving, consistent bite at lower temperatures and reduced noise may be paramount. For frequent downhill driving or towing, high-temperature stability and resistance to fade are more important than pristine wheels.

The refined approach is to discuss pad choice with your technician in terms of your driving environment: city vs. highway, climate, load, and driving style. Matching pad material to usage is not about aggressive performance; it is about consistent, predictable behavior across the widest range of real-world conditions you actually encounter. That consistency is itself a form of safety.

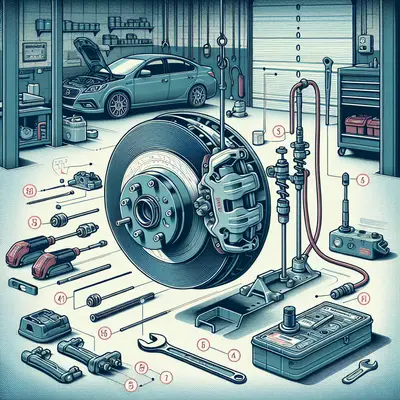

Exclusive Insight 3: The Hidden Importance of Clean, Free-Moving Hardware

When most people hear “brake job,” they picture pads and rotors. Yet a truly premium service pays equal attention to the quiet, overlooked components: caliper slide pins, anti-rattle clips, pad shims, and hub surfaces. These are not cosmetic; they are fundamental to safe, even braking.

Slide pins that are contaminated or poorly lubricated can cause one pad to drag more than the other, leading to uneven wear, overheating, and subtle steering pull under braking. Dirty or corroded hub faces may prevent rotors from sitting perfectly flush, contributing to lateral runout that the driver experiences as pedal pulsation. Worn anti‑rattle hardware can allow pads to move or chatter, compromising both comfort and confidence.

A sophisticated brake maintenance standard expects the technician to clean and properly lubricate slide pins with high-temperature brake grease, de‑rust hub surfaces, and replace damaged or fatigued hardware rather than reusing it by default. The difference may not always be visible, but it is unmistakable in how smoothly and consistently the car decelerates over thousands of miles.

Exclusive Insight 4: Seasonal Brake Inspections as a Safety Tradition

While oil changes are on nearly every driver’s calendar, brake inspections are too often reactive—performed only when a noise appears or performance obviously degrades. For safety‑first owners, scheduling seasonal brake evaluations is a quiet but powerful tradition.

Before winter, verify pad thickness, rotor condition, and fluid health to ensure the system is at its best for cold, wet, and low‑traction conditions. In regions that use road salt, corrosion can accelerate on calipers, lines, and backing plates, sometimes seizing components or prematurely wearing pads. After winter, a follow‑up inspection can catch early rust, sticking slide pins, or uneven wear before they become serious failures or expensive repairs.

These seasonal checkpoints need not be elaborate or costly. A professional visual and mechanical inspection—measuring pad thickness, checking for leaks, examining hoses, evaluating pedal feel, and inspecting parking brake operation—provides peace of mind and, more importantly, confirms that your vehicle’s stopping performance matches its apparent outward condition. Elegance in ownership includes ensuring that beauty and safety align.

Exclusive Insight 5: Practicing “Predictive Braking” to Extend System Life

Exceptional brake maintenance extends beyond the workshop and into daily driving habits. The way you modulate the pedal can significantly influence not only brake longevity but also how predictably the system performs in emergency situations.

“Predictive braking” is the practice of reading traffic several vehicles ahead, gently easing off the accelerator earlier, and applying measured, progressive brake pressure instead of abrupt, late inputs. This habit reduces heat buildup in pads and rotors, minimizes the risk of glazing or hot spots, and lowers the frequency of ABS interventions. Over time, it results in more consistent rotor surfaces, quieter operation, and extended pad life—all while enhancing comfort for passengers.

From a safety standpoint, predictive braking also keeps more braking capacity in reserve. By avoiding repeated hard stops where possible, you maintain more consistent fluid temperatures and preserve braking performance for when it is truly needed. It is a form of driving etiquette that feels smooth from inside the cabin yet quietly protects the mechanical integrity of the brake system mile after mile.

Conclusion

Brake maintenance, at its most refined, is less about reacting to crises and more about cultivating quiet reliability. It is expressed in deliberate choices—fresh, properly specified brake fluid; carefully selected pad materials; cleaned and lubricated hardware; seasonal inspections; and thoughtful driving techniques. For the safety‑first driver, these are not indulgences; they are essential expressions of responsibility.

When you approach brake care as a subtle discipline, every stop becomes a quiet confirmation that your decisions, attention, and standards are working together. The reward is not simply shorter stopping distances—it is the composed confidence of knowing that your vehicle’s most critical safety system has been maintained with intention, precision, and respect.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brakes and Safety](https://www.nhtsa.gov/equipment/brakes) - U.S. government guidance on brake systems and safety considerations

- [AAA – How to Know When Your Brakes Need Servicing](https://www.aaa.com/autorepair/articles/how-to-know-when-your-brakes-need-servicing) - Practical overview of warning signs and maintenance intervals

- [Car and Driver – Brake Fluid: What It Is and How It Works](https://www.caranddriver.com/research/a32865589/brake-fluid/) - Detailed explanation of brake fluid types, hygroscopic behavior, and service recommendations

- [Consumer Reports – How to Make Your Brakes Last Longer](https://www.consumerreports.org/cars/car-repair-maintenance/how-to-make-your-brakes-last-longer-a1474815919/) - Discussion of driving habits and maintenance practices that extend brake life

- [MIT – Emergency Braking and Vehicle Control Research](https://ocw.mit.edu/courses/16-863j-system-safety-fall-2016/pages/lecture-notes/) - Technical lecture materials related to vehicle control and system safety (includes braking-related concepts)

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.