Brake performance is one of the few automotive qualities you truly feel every time you drive. The calm certainty of a controlled stop, the absence of noise or vibration, and the way the vehicle settles gracefully instead of nosediving—these are the subtle hallmarks of a well‑maintained braking system. For drivers who value refinement, safety, and mechanical integrity, brake maintenance isn’t a reluctant chore; it is an ongoing craft.

This guide examines brake care through a more elevated lens—focusing not just on avoiding failure, but on preserving precision, consistency, and confidence. Along the way, you’ll find five exclusive, often-overlooked insights that align with the expectations of drivers who refuse to treat safety as an afterthought.

Understanding Brake Wear as a System, Not a Part

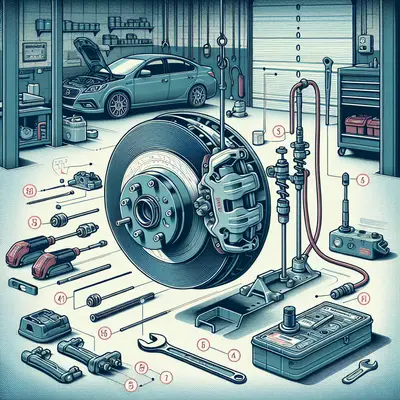

Most drivers think of brake maintenance as “replacing pads when they’re worn out.” That view is far too narrow. A braking event is an orchestrated interaction among pads, rotors, calipers, hydraulic fluid, hoses, ABS modules, wheel bearings, and tires. Any weakness in this chain can diminish stopping performance long before warning lights appear.

High-quality pads on overheated, glazed rotors will feel inconsistent. Perfect rotors with aging, moisture-contaminated fluid can deliver a long, spongy pedal even though nothing appears “broken.” Worn suspension components or imbalanced tire pressure can lengthen stopping distances because the tires cannot maintain ideal contact with the road under load. A refined approach to maintenance considers the entire braking ecosystem—not simply the parts with obvious wear indicators.

This systems-based perspective is particularly important on modern vehicles with advanced driver-assistance systems (ADAS). Features such as adaptive cruise control, automatic emergency braking, and stability control all depend on predictable braking responses. If the system cannot reliably achieve the deceleration its software expects, safety margins are reduced even if you never see a fault message.

Five Exclusive Insights for Brake-Conscious Owners

For drivers who prioritize subtlety, safety, and control, these five insights go beyond basic advice and move into the realm of purposeful, elevated maintenance.

1. Pedal Feel Is a Diagnostic Tool, Not a Preference

Most people describe pedal feel as “soft” or “firm,” almost as if it were a matter of taste. In truth, how the pedal responds is one of the most sensitive diagnostic instruments you have.

A pedal that initially feels firm and then slowly sinks during a long stop may signal internal fluid leakage in the master cylinder. A pedal that remains consistently soft after several stops can indicate air in the system or flexible hoses that are ballooning under high pressure. A pedal that feels rough, notchy, or “gravelly” suggests uneven pad deposits or rotor surface irregularities—even when braking power seems adequate.

Cultivate the habit of noticing pedal behavior under varied conditions: cold starts, downhill braking, highway exits, and stop‑and‑go city traffic. Refinement here means paying attention to small changes over time, not just dramatic failures. When you can articulate to a technician that the pedal feels different at the end of a long descent than it does at the first traffic light, you provide invaluable information for precise diagnosis.

Key takeaway: The brake pedal is your first and most immediate sensor. Treat changes in feel as an early warning system, not as a quirk to ignore.

2. Brake Fluid Condition Matters as Much as Brake Pad Thickness

Pads and rotors are visible; brake fluid is not. Yet from a performance and safety standpoint, fluid quality can be just as crucial. Brake fluid is hygroscopic—it absorbs moisture over time. That moisture lowers the fluid’s boiling point, making the system far more vulnerable to “brake fade” under hard or repeated braking, such as on mountain roads or in spirited driving.

Even if you rarely push your brakes aggressively, moisture can corrode internal components, from ABS valves to caliper pistons, slowly undermining reliability. Many manufacturers recommend changing brake fluid every 2–3 years, regardless of mileage—a guideline that is frequently neglected.

For those who value a consistently firm, predictable pedal, fluid replacement is not an optional “extra”; it is a foundational service. Using the correct specification fluid (DOT 3, 4, or 5.1 as specified by your manufacturer) and adhering to a time-based interval will preserve that reassuring, linear response you rely on in an emergency.

Key takeaway: Treat brake fluid as a time-sensitive safety component, not a perpetual background fluid.

3. Rotor Finish and Pad Bedding Define the Quality of Every Stop

Rotors and pads do more than simply press against each other; they create a friction interface that needs to be properly established and maintained. Even with premium parts, poor surface preparation or improper break‑in can lead to shudder, noise, and uneven braking.

When rotors are replaced or resurfaced, a uniform, fine, non-directional finish is critical. Deep grooves, machining marks, or rust patches can all distort how the pad material transfers to the rotor. New pads should be “bedded in” according to the manufacturer’s procedure—typically a series of progressively stronger stops from moderate speeds, allowing the brakes to cool between applications. This process lays down a consistent layer of pad material on the rotor surface, stabilizing friction and minimizing the risk of future judder.

Owners who prioritize refinement may want to confirm with their service provider that rotors are properly cleaned (to remove protective coatings or machining residue) and that the vehicle is test-driven to complete the initial bedding cycle. A well-bedded system feels composed and silent even in firm stops, with no sense of grabbing or pulsing.

Key takeaway: The quality of the rotor surface and the pad bedding process determine how “luxurious” or crude your braking feels—regardless of how much you spent on parts.

4. Environmental Conditions Quietly Shape Brake Performance

Where and how you drive has a profound, often invisible influence on brake health. City drivers face frequent stop‑and‑go braking, building heat and wearing pads quickly. Highway‑biased vehicles may see more corrosion than wear, as brakes are used less intensely and moisture has more time to accumulate on rotors and hardware.

Coastal environments and regions that use road salt are especially harsh on metal components. Caliper slide pins can seize, shield plates can rust, and rotor hats may corrode long before the underlying friction surfaces are worn out. When calipers cannot move freely, pads may drag, resulting in premature wear, noise, and uneven braking.

Discerning owners can mitigate these risks by tailoring inspection intervals to their environment rather than relying solely on generic mileage-based schedules. In harsh climates, annual or even semiannual brake inspections—focusing not just on pad thickness, but on hardware condition and freedom of movement—can dramatically extend system life and reliability.

Key takeaway: Maintenance intervals should reflect your climate and driving pattern. Brake care in a dry, mild region is fundamentally different from brake care in a coastal or winter-salt environment.

5. True Brake Excellence Begins at the Tire Contact Patch

Brake systems do not stop vehicles; tires do. The brakes merely convert motion into heat and transfer that load to the tires. No matter how advanced your brake components are, they can only deliver as much deceleration as the tires can transmit to the road.

This has several implications. Worn or low-quality tires, incorrect tire pressures, and misaligned suspension all effectively weaken your braking, even if the pads and rotors are new. Anti-lock braking systems (ABS) and stability control rely on the assumption that your tires will provide a predictable level of grip; when tire performance is compromised, those systems must intervene more often and more aggressively, sometimes lengthening stopping distances to maintain control.

For the safety-conscious driver, viewing brakes and tires as a single safety system is essential. Investing in high-quality, seasonally appropriate tires and checking pressures regularly is, in practical terms, as important as using quality brake components. The finest brake job is incomplete if the tires cannot fully capitalize on its capabilities.

Key takeaway: Your braking “upgrade” begins with the four small contact patches where rubber meets the road.

Elevating Your Personal Brake Maintenance Standard

Taking brake maintenance seriously does not require becoming a technician, but it does benefit from a more deliberate mindset. Start by redefining what “good brakes” mean to you: not merely the absence of noise or warning lights, but a consistent, quiet, and confident response under any conditions.

Develop a personal standard that includes:

- Time-based brake fluid changes, documented and scheduled like an annual health check.

- Periodic brake inspections that review pad thickness, rotor condition, hardware freedom, and signs of corrosion or leakage.

- A habit of noticing changes in pedal feel, steering feedback under braking, and any new noises—subtle clues that deserve prompt attention.

- A commitment to quality tires and correct pressures, recognizing their role as an extension of your braking system.

In the end, refined brake maintenance is less about reacting to problems and more about preserving grace under pressure. The reward is not only shorter stopping distances, but a driving experience defined by calm assurance. Every controlled, effortless stop becomes a quiet affirmation that safety, when thoughtfully maintained, can feel as elegant as it is effective.

Conclusion

For the discerning driver, brake care is not a reluctant line item on a service invoice; it is a disciplined practice that shapes every journey. By treating pedal feel as a diagnostic tool, respecting brake fluid as a critical consumable, insisting on proper rotor and pad preparation, adapting to environmental realities, and honoring the tire’s role in braking, you create a safety envelope that is both robust and refined.

This elevated approach does more than protect components—it protects your confidence. The next time you ease into a firm, controlled stop, remember: that quiet moment of assurance was engineered in advance, through deliberate choices about how you maintain the most important system on your vehicle.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brakes](https://www.nhtsa.gov/equipment/brakes) – Federal safety information on brake systems, performance, and recalls.

- [U.S. Department of Transportation – Brake System Safety](https://www.transportation.gov/mission/safety/brake-system-safety) – Guidance on brake system components and safe operation from a regulatory perspective.

- [Society of Automotive Engineers (SAE) – Technical Papers on Brake Systems](https://www.sae.org/search/?qt=brake%20system&sort=relevance&content-type=%28%22TECHPAPER%22%29) – Research-based insights into brake design, performance, and fluid characteristics.

- [University of Wisconsin–Madison Engineering – Fundamentals of Friction Brakes](https://minds.wisconsin.edu/handle/1793/6906) – Educational material on brake friction, rotor interactions, and heat management.

- [Continental – Brake Fluid: Properties and Maintenance](https://www.continental-aftermarket.com/en-sg/passenger-cars/know-how/brake-systems/brake-fluid) – Technical overview of brake fluid behavior, moisture absorption, and replacement intervals.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.