For drivers who regard their vehicle as more than transport—who value composure, control, and quiet confidence—brake maintenance is not a chore; it is a discipline. Beyond routine service intervals and dashboard warnings lies a more refined approach: one that listens, observes, and anticipates. This is the quiet art of brake care, practiced by those who prefer their safety engineered rather than improvised.

Below, we explore a sophisticated maintenance philosophy, along with five exclusive insights tailored to drivers who refuse to treat brake safety as an afterthought.

Understanding Brake Health as a System, Not a Single Part

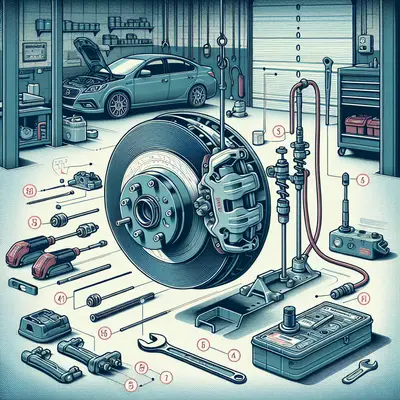

Most service conversations reduce “brakes” to pads and rotors, but a discerning owner recognizes a fully integrated system at work. The modern brake assembly includes hydraulic lines, calipers, pads, rotors (or drums), the master cylinder, the brake booster, electronic sensors, and—often—advanced control modules for ABS and stability systems.

Treating brake care as a system means moving beyond pad wear alone:

- A slightly spongy pedal may be the first hint of moisture-contaminated fluid, not just “old brakes.”

- Gentle pulsation can point to rotor thickness variation, caliper sticking, or improper torque on wheel lugs.

- Uneven pad wear can reveal subtle issues: a lazy caliper slide pin, contaminated pad material, or misaligned hardware.

By reframing maintenance around the entire system, owners can request more intelligent inspections, insist on component-level detail in service reports, and make decisions that extend both performance and longevity.

The Listening Ritual: Fine-Tuning Your Ear for Subtle Brake Changes

A refined driver does not wait for scraping, grinding, or dashboard warnings. Instead, they cultivate a quiet listening ritual every time they drive. This is less about paranoia and more about creating a baseline of normal behavior—so that even subtle deviations stand out.

Listen and feel for:

- **Timbre of sound:** A clean, healthy brake application is largely silent or a muted whisper. A faint, recurring chirp at low speeds can be an early indicator of wear indicators touching the rotor.

- **Pedal feedback:** A firm, progressive pedal that responds predictably is ideal. Softness, sudden extra travel, or a “springy” sensation is a cue for inspection, even if stopping distances still seem normal.

- **Consistency across conditions:** Differences between cold and warm braking, dry and wet roads, or city and highway use can reveal early issues that a cursory test drive might miss.

Turn this into a discreet ritual: once a week, at low speed in a safe, empty area, perform a few deliberate stops. Pay attention to pedal feel, sound, steering wheel feedback, and any pull to one side. This measured self-check can flag concerns long before they become repairs under duress.

Five Exclusive Insights for Owners Who Refuse to Compromise

1. Brake Fluid Is Not “Lifetime”—It’s Your Invisible Safety Margin

Brake fluid is hygroscopic; it slowly absorbs moisture from the air, even in a sealed system. Over time, this lowers the fluid’s boiling point and invites internal corrosion. Under hard or repeated braking, overheated, moisture-laden fluid can boil, introducing compressible vapor into the system and degrading pedal feel.

Refined practice:

- Treat brake fluid as a **critical consumable**, not a background fluid. Many manufacturers recommend flushing approximately every 2–3 years, but spirited driving, towing, or mountainous terrain can justify shorter intervals.

- Ask your shop for a **brake fluid boiling point test** rather than relying only on age or mileage. This provides a quantitative, not just approximate, basis for service.

- Insist on fluid that meets or exceeds your vehicle’s specified DOT standard; improper fluid can compromise system performance, particularly with ABS and stability control.

2. Pad Compound Selection Should Match Your Driving Personality

Brake pads are not generic. The friction material—ceramic, semi-metallic, low-metallic, or specialized performance compounds—shapes everything from pedal feel to noise profile and rotor wear.

For the meticulous driver:

- **Ceramic pads** typically deliver quieter operation, low dust, and smooth, progressive braking—ideal for drivers who value refinement and cleanliness.

- **Semi-metallic pads** often provide stronger initial bite and better high-heat performance but may be noisier and more abrasive to rotors.

- Higher-end OEM or premium aftermarket pads are engineered to harmonize with your vehicle’s rotor metallurgy, ABS tuning, and NVH (noise, vibration, harshness) characteristics.

Rather than accepting “whatever’s standard,” request a discussion of pad compounds and their characteristics. Choosing the right material transforms braking from merely adequate to tailored.

3. Rotor Quality and Finish Quietly Dictate Brake Elegance

Rotors are often treated as interchangeable discs of metal, but their metallurgy, machining tolerances, and surface finish profoundly influence stopping smoothness and noise. Low-quality, poorly machined rotors are more prone to warping sensations, vibration, and uneven pad deposition.

For elevated maintenance:

- Opt for **rotors with precise machining and balanced construction**, ideally from reputable OEM or premium brands.

- If resurfacing is suggested, ensure the shop respects **minimum thickness specifications** and uses proper equipment to maintain parallelism and smooth finish; if not, replacement is often the more refined—and safer—choice.

- Avoid aggressive driving or heavy braking in the first few hundred miles on new pads and rotors; follow a proper **bedding-in procedure** to allow even transfer of pad material, which can dramatically improve smoothness and longevity.

4. Caliper and Hardware Care: The Often-Ignored Source of Uneven Wear

Many brake services focus only on pads and rotors, leaving caliper slide pins, abutment clips, and shims as an afterthought. Yet these components determine how evenly and gracefully your brakes engage. Sticking slide pins or corroded hardware can cause one pad to do most of the work, leading to noise, pulling, and premature wear.

A meticulous standard includes:

- Removal, cleaning, and **proper lubrication of slide pins** with high-temperature, brake-specific lubricant.

- Inspection and replacement of **pad hardware** (clips, shims, springs) rather than simply transferring old, fatigued pieces to new pads.

- A visual confirmation that the caliper pistons move freely and retract properly, particularly on vehicles that experience winter road salt or infrequent use.

This level of attention yields quieter operation and more consistent braking, especially during low-speed, light-pedal applications where imperfections are most noticeable.

5. Seasonal and Usage-Based Adjustments: One Schedule Does Not Fit All

Conventional brake maintenance advice revolves around mileage alone, but sophisticated ownership accounts for how and where the vehicle is driven. Hilly environments, urban stop-and-go traffic, performance driving, towing, and extreme climates all accelerate brake wear in different ways.

To refine your intervals:

- In heavy city or mountainous use, treat your service intervals more aggressively than the owner’s manual minimums. Have your brakes inspected at each tire rotation, not just at arbitrary mileage markers.

- If you store a vehicle or drive it infrequently, factor in **time-based degradation**: corrosion on rotors, sticking calipers, and moisture absorption in brake fluid occur even with low mileage.

- For EVs and hybrids, regenerative braking reduces pad wear, but rust on rotors and caliper inactivity can become the primary concerns. Periodically perform deliberate, friction-based stops to keep rotors clean and components exercised.

This usage-centric approach ensures your maintenance strategy reflects your driving reality, not someone else’s average.

Elevating Your Relationship with Your Brake Specialist

A premium brake experience extends to how you work with your technician or service center. Instead of passively accepting a generic “brake job,” consider the relationship a collaboration:

- Request **measured details**: pad thickness (in millimeters), rotor thickness, and runout readings rather than vague “they’re getting low” commentary.

- Ask for **before-and-after photos** of pads, rotors, and calipers, especially if you are not present during service. A reputable shop will welcome this transparency.

- Discuss **component choices**—pads, rotors, hardware, and fluid brand—so you understand not only what is being replaced, but why.

By engaging at this level, you ensure that the work performed aligns with your expectations of refinement and safety, not just basic compliance.

Conclusion

Truly elevated brake maintenance is quiet, precise, and intentional. It is less about reacting to warning lights and more about understanding the orchestra of components that bring your vehicle to a controlled, graceful stop. When you listen carefully, choose components intelligently, and service the system as a whole, you move beyond merely “passing inspection” and into a realm of confident, composed braking that befits a meticulous driver.

In a world where many accept “good enough,” the quiet art of brake care is a subtle luxury: the knowledge that every stop is as deliberate and controlled as the way you choose to drive.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brake Safety Overview](https://www.nhtsa.gov/brakes) – Federal guidance on brake system safety, component function, and common issues.

- [U.S. Department of Transportation – Brake Fluid Standards (FMVSS No. 116)](https://www.ecfr.gov/current/title-49/subtitle-B/chapter-V/part-571/section-571.116) – Technical regulations governing brake fluid performance and classifications (DOT standards).

- [AAA – The Basics of Braking Systems](https://exchange.aaa.com/automotive/automotive-testing/basics-of-braking-systems/) – Clear, consumer-focused explanation of brake system components and maintenance needs.

- [Bridgestone – Types of Brake Pads and Their Differences](https://www.bridgestonetire.com/learn/maintenance/types-of-brake-pads/) – Overview of brake pad compounds and their characteristics for different driving styles.

- [YourMechanic – How Long Does Brake Fluid Last?](https://www.yourmechanic.com/article/how-long-does-brake-fluid-last) – Practical discussion of brake fluid lifespan, contamination, and service recommendations.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.