For discerning drivers, brake maintenance is not a chore—it is a quiet ritual of respect for precision, safety, and control. Your braking system is the final arbiter between potential and peril, and how you care for it defines the quality of every journey. This is not about squeezing extra miles from worn pads; it is about cultivating a level of vigilance that matches the performance and refinement of the vehicles we choose to drive.

Below, we explore a more elevated approach to brake care—one that favors intention over improvisation, and insight over guesswork—along with five exclusive perspectives that safety‑focused owners rarely see in standard maintenance guides.

Reframing Brake Maintenance as a Safety Standard, Not a Schedule

Most maintenance advice reduces braking care to mileage intervals and calendar reminders: change pads at X miles, flush fluid every Y years. While helpful, that mindset is ultimately reactive. A sophisticated approach to brake maintenance treats the system as a dynamic safety instrument that evolves with how, where, and what you drive.

Driving in dense urban traffic, descending mountain roads, or towing on weekends exerts dramatically different stress on your brakes compared with steady highway commuting. The same manufacturer schedule can be conservative in one scenario and surprisingly optimistic in another. Instead of asking, “Have I reached the interval?” refined owners ask, “Has my driving placed higher thermal and mechanical demands on my brakes than this interval assumes?” The answer often supports more proactive inspections, particularly of pads, rotors, and brake fluid condition.

This mental shift—from mileage boxes to operational realities—produces a subtler, more accurate sense of when your brakes truly need attention. It also lays the groundwork for more nuanced conversations with your service professional, where you talk not only about distance traveled, but about load, climate, and driving style.

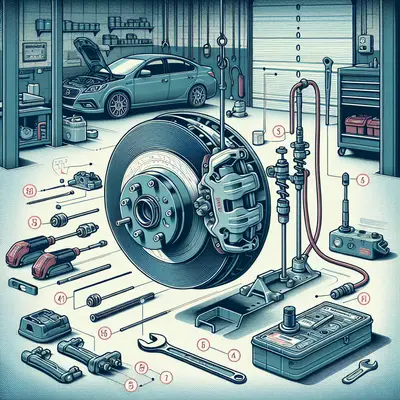

Understanding Your Brakes as a System, Not Just Wear Items

Fine driving is about consistency: the ability to deliver the same measured stop, every time. Achieving that consistency demands that you view the brakes as a system of interdependent components rather than a collection of parts to be replaced piecemeal.

Pads and rotors are the obvious wear items, but premium braking confidence is shaped by the less visible elements: calipers that move smoothly without binding, rubber hoses that maintain structural integrity, and high‑quality fluid that resists moisture and maintains its boiling point. A sophisticated maintenance strategy looks beyond pad thickness and rotor grooves to ask deeper questions: Is pedal travel lengthening? Is there a subtle left‑right imbalance when stopping firmly? Does the ABS engage too readily in conditions where it previously did not?

By regarding your brakes as a total system, you avoid the common trap of addressing only what is visibly worn and instead maintain harmony between components. The result is not just shorter stopping distances, but predictable, linear response—a trait refined drivers value above raw power.

Five Exclusive Insights for Owners Who Refuse to Compromise

1. Brake Fluid as a Precision Component, Not a Placeholder

Brake fluid is often treated as a background fluid—changed infrequently, if at all. In reality, it is the medium that translates your intent into controlled stopping force. Because it is hygroscopic (it absorbs moisture over time), its performance slowly degrades long before you see any warning lights or obvious issues.

Moisture in brake fluid lowers its boiling point, which becomes critical during repeated hard stops, spirited driving, or descending long grades. When overheated, fluid can vaporize in localized pockets, creating a compressible gas and resulting in a soft, spongy pedal or, in extreme cases, temporary brake fade just when control matters most.

A refined maintenance practice treats fluid testing as routine, not exceptional. Using a professional‑grade brake fluid tester or asking your service facility to measure moisture content and boiling point provides objective evidence for a fluid flush—often earlier than the generic two‑ to three‑year guidance. Selecting a high‑quality fluid that meets or exceeds your vehicle’s specification, and insisting it be opened fresh (not from a half‑used container), is a small detail that yields significant safety reserves under demanding conditions.

2. Heat Patterns on Rotors as a Window Into Driving and Setup

Most owners notice rotors only when they are scored, rusted, or warped. But rotor surfaces tell a more nuanced story. Subtle heat discoloration (light blue or purple hues), uneven pad deposits, or micro‑cracking near the edges are early reflections of how your brakes are being used—even before vibration or pulsation becomes evident.

Consistent light coloration across the rotor suggests balanced braking. Darker hotspots can indicate calipers that are not releasing cleanly, pads that are mismatched to your driving, or a braking technique that leans heavily on long, light pressure rather than firm, decisive applications. The latter can promote uneven pad material transfer, leading to the “warped rotor” sensation many drivers experience.

Incorporating a careful visual examination of rotor surfaces into regular tire rotations or seasonal checks allows you to intervene early: addressing sticking calipers, adjusting driving style on steep descents, or choosing pads better suited to your environment. This is a level of interpretation most quick‑service operations simply do not provide—but it is accessible to any owner who chooses to look with intention.

3. Brake Pedal Feel as an Early Diagnostic Instrument

While many drivers notice only obvious changes—squealing, grinding, or dashboard warnings—the brake pedal itself is an exquisitely sensitive diagnostic tool. The key is to develop a personal reference: how your pedal feels when the system is in peak condition.

Once you are familiar with your baseline, subtle variations become meaningful. Slightly increased travel before engagement, a pedal that firms up after a rapid pump, or a faint pulsing under steady pressure can each signal different developing issues: early air intrusion or fluid degradation, minor rotor thickness variation, or uneven pad wear. These nuances often appear long before performance drops to an unsafe level.

The refined practice is to test pedal feel consciously a few times a month, ideally on a familiar stretch of road at moderate speed. Apply a series of controlled stops with consistent pressure, paying attention to initial bite, progression, and release. This small ritual—taking less than a minute—turns your own perception into an early‑warning system that supplements periodic professional inspections.

4. Environmental and Lifestyle Factors That Quietly Accelerate Wear

Brake wear is not dictated by mileage alone; it is heavily shaped by your environment and lifestyle. Cold climates with salted roads promote corrosion on calipers, sliders, and backing plates, sometimes leading to seized components while pads still appear serviceable. Coastal air can accelerate rust on exposed metal, subtly impacting braking consistency and caliper operation.

Short, frequent trips where brakes never fully dry or heat to normal operating temperature can leave moisture on components, encouraging surface rust that interferes with pad movement. Urban hills, heavy cargo, roof boxes, and towing all place substantial additional load on your braking system, demanding more frequent inspections even when an odometer suggests otherwise.

Sophisticated maintenance accounts for these realities by tightening inspection intervals after harsh winters, having slide pins and caliper hardware cleaned and lubricated more often in corrosive environments, and aligning pad and rotor choice with the actual duty cycle of the vehicle. This tailored approach keeps your braking system honest to your real life, not an idealized average.

5. Choosing Brake Components as a Safety Strategy, Not a Cost Decision

The difference between an adequate brake job and an exceptional one is rarely visible from the driver’s seat—until a demanding moment reveals it. For owners attentive to safety and refinement, component selection becomes a strategic choice, not a budget exercise.

High‑quality pads from reputable manufacturers are engineered not just for stopping power but for consistent friction across a wide temperature range, reduced fade, and predictable pedal feel. Premium rotors maintain tighter tolerances for thickness and runout, minimizing the risk of future vibration and uneven wear. Original equipment (OE) or high‑quality OE‑equivalent parts often integrate noise‑damping shims, chamfers, and slot designs that contribute to quiet, composed braking under varied conditions.

A sophisticated practice is to discuss your priorities—smoothness, low dust, high‑speed stability, or heavy‑load capability—with a trusted technician, then select components that match those priorities rather than defaulting to the lowest price option. In doing so, you curate a braking experience that reflects your values: composure, predictability, and an unapologetic margin of safety.

Integrating Professional Expertise With Personal Vigilance

Even the most attentive owner benefits from an expert’s eye. The aim is not to replace professional service, but to elevate it through informed partnership. Arriving at your service appointment with specific observations—“The pedal travel has increased slightly over the last two months,” or “There is a faint pulsation at moderate speed downhill”—guides your technician toward more precise diagnostics.

Equally, choosing a service provider that welcomes thoughtful questions is essential. Ask how they measure rotor thickness and runout, whether they inspect caliper slide movement, and what brake fluid test method they use. A professional comfortable discussing these details is more likely to take the same care with your vehicle that you do.

By combining structured professional inspections with your own ongoing awareness of sound, feel, and performance, you construct a dual layer of protection. It is this redundancy—anticipation backed by expertise—that underpins truly uncompromising brake safety.

Conclusion

Brake maintenance, approached with discipline and intention, becomes far more than a line item on a service invoice. It evolves into a quiet craft: an ongoing dialogue between you, your vehicle, and the conditions you ask it to master. By treating brake fluid as a precision medium, reading rotor surfaces as data, refining your sensitivity to pedal feel, respecting environmental stresses, and choosing components deliberately, you move beyond basic compliance into a realm of curated safety.

For the driver who expects more, this is where confidence truly resides—not in the absence of problems, but in the presence of careful, continuous attention to the system that stands between momentum and stillness, every time you press the pedal.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Vehicle Safety and Brakes](https://www.nhtsa.gov/equipment/brakes) – Federal safety information and guidance on braking systems and performance

- [SAE International – Brake Fluid Properties and Performance](https://www.sae.org/news/2019/01/brake-fluid-moisture) – Technical discussion on brake fluid moisture absorption and its effects on safety and braking performance

- [AAA – Understanding Your Car’s Braking System](https://www.aaa.com/autorepair/articles/understanding-your-cars-braking-system) – Consumer‑focused explanation of how brake components work and why maintenance matters

- [Car Care Council – Brake System Maintenance Guidelines](https://www.carcare.org/brakes-antilock-brakes/) – Industry‑backed recommendations on inspection intervals and key brake service practices

- [University of Texas at Austin – Automotive Braking Systems Overview (ME Dept.)](https://www.me.utexas.edu/~longoria/papers/auto_brakes_longoria.pdf) – Educational resource detailing the engineering principles behind modern braking systems and their behavior under load

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.