Modern brake systems are masterpieces of controlled force, quietly converting speed into safety with every press of the pedal. For drivers who demand more than “good enough,” understanding this system is not a technical indulgence—it is a safety investment. This briefing explores how refined attention to your brakes translates into composure, confidence, and control on every drive, and offers five exclusive insights that safety‑focused owners rarely find in standard maintenance guides.

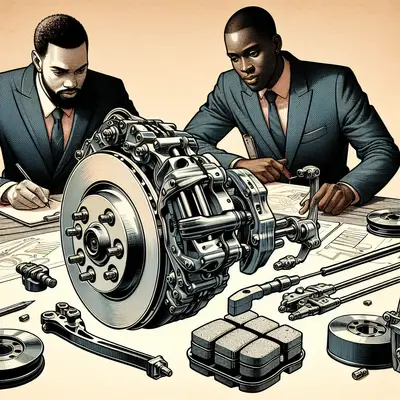

Understanding the Architecture of Modern Brakes

At its core, a brake system is an elegant energy manager. When you press the pedal, your kinetic energy—the motion of your vehicle—is converted into heat through friction at the wheels. Hydraulic pressure amplifies the modest effort of your foot into force at the calipers or wheel cylinders, squeezing pads against rotors or shoes against drums.

Modern systems add several layers of intelligence atop this mechanical foundation. Anti-lock braking systems (ABS) modulate brake pressure to prevent wheel lockup, preserving steering control during hard stops. Electronic brakeforce distribution (EBD) subtly adjusts how much force each wheel receives, accounting for load, weight transfer, and road conditions. Brake assist systems recognize panic braking and automatically amplify pedal pressure, compensating for the hesitation many drivers exhibit in emergencies.

Viewed as a unified whole rather than a collection of parts, the brake system becomes less mysterious and more strategic. Each component—fluid, hoses, pads, rotors, sensors, control modules—plays a defined role in orchestrating predictable, repeatable deceleration. For the discerning driver, the objective is not simply “stopping,” but stopping consistently, under control, and with a safety margin in reserve.

The Hidden Language of Pedal Feel

To the attentive driver, the brake pedal is a highly communicative interface. Subtle variations in resistance, travel, and feedback often reveal the state of the system long before a warning light illuminates.

A firm, predictable pedal that engages brakes consistently at the same height is the baseline standard. If the pedal gradually becomes “spongy” or sinks further toward the floor over time, it may indicate air in the hydraulic lines, aging brake fluid, or internal component wear. Conversely, an unusually hard pedal can suggest restrictions in the hydraulic system, failing boosters, or vacuum-related issues.

Pedal pulsation—rhythmic vibration under light or moderate braking—is often associated with uneven rotor thickness or hot spots, sometimes stemming from improper torque on lug nuts or aggressive braking under high heat. A slow, creeping pedal during steady pressure may indicate internal fluid bypass in the master cylinder, a concern that warrants immediate professional evaluation.

For the safety-conscious owner, the practice is simple but powerful: notice and mentally “log” pedal changes. A brief, periodic check—such as a firm application on a straight, empty road at moderate speed—can help you build a memory of what “normal” feels like. Any departure from that norm is your cue to investigate before a minor irregularity matures into a critical fault.

Heat, Fade, and the True Limits of Your Brakes

Brakes are ultimately thermodynamic devices: their true limitation is heat management, not raw stopping power. Under everyday conditions, most systems operate comfortably within their design envelope. The risks emerge when heat accumulates faster than it can dissipate—during repeated hard stops, mountain descents, spirited driving, or towing.

Brake fade occurs when pads and fluid can no longer perform reliably at elevated temperatures. As pads overheat, their friction characteristics change; you may need more pedal pressure for the same stopping effect, or you may feel a vague, unresponsive sensation underfoot. If brake fluid overheats and begins to boil, microscopic vapor bubbles form in the hydraulic system. Because vapor compresses far more than liquid, the pedal can suddenly feel soft, long, or nearly ineffective.

Sophisticated drivers learn to manage heat proactively. On long downhill stretches, they favor lower gears and engine braking, using the brakes intermittently and firmly rather than lightly and continuously. After a series of intense stops, they allow a short period of gentle driving to enable cooling rather than immediately parking with extremely hot components.

An often-overlooked point: high-performance or “sport” pads are not automatically safer for daily use. Many such compounds are optimized for high-temperature operation and may perform poorly when cold—precisely the condition of most city commutes or short trips. A pad compound that matches your actual driving profile is a quieter, more effective upgrade than simply choosing the most aggressive option available.

Beyond Visual Checks: Fluid, Hoses, and the Subtle Vulnerabilities

Most brake inspections focus on visible wear items such as pads and rotors, yet some of the most consequential vulnerabilities lie hidden in components that age quietly.

Brake fluid is hygroscopic—it gradually absorbs moisture from the atmosphere. Over time, this lowers its boiling point and promotes internal corrosion. While fluid may still appear clear or pale in the reservoir, its performance can be significantly degraded. Serious owners follow manufacturer intervals or adopt a conservative two- to three-year flush cadence, especially in humid climates or areas with significant elevation changes.

Rubber brake hoses, though simple in appearance, are critical conduits of pressure. With age, they can swell internally, restricting fluid flow, or develop fine cracks externally that may not be immediately obvious. Symptoms can include uneven braking, residual drag at a wheel, or inconsistent pedal response. Replacing aging hoses with high-quality OEM or carefully selected upgraded components is not a cosmetic decision—it is a structural investment in reliability.

Caliper slide pins and hardware also merit attention. When neglected, they can seize or bind, causing one pad to do disproportionate work, leading to uneven wear, pulling during braking, or overheating at a single wheel. A refined brake service does more than swap pads; it restores correct motion, lubrication, and alignment across the entire system.

In essence, the brake system’s true condition is only partially visible through the wheel. The more of its hidden elements you consider—fluid, hoses, internal seals, hardware—the more complete your safety picture becomes.

Tire Contact: The Often-Ignored Partner in Braking

Brakes do not stop the car alone; tires do. The finest braking system cannot exceed the grip available at the contact patch where rubber meets the road. For drivers who care deeply about stopping performance, tire selection and condition are as consequential as any hardware upgrade.

Tread depth, compound, and tire age all influence available traction. Even with adequate tread, an aging tire can harden, reducing its ability to conform to road irregularities and grip effectively—particularly in wet or cold conditions. A tire near the legal tread limit often provides significantly less wet-weather braking performance than many drivers realize, lengthening stopping distances even when the brake system itself is flawless.

Tire pressure, too, plays a central role. Underinflated tires deform excessively, increasing heat and reducing predictability under hard braking. Overinflated tires reduce the contact patch, potentially diminishing grip and making ABS interventions more frequent. Adhering to the vehicle manufacturer’s recommended pressures—checked when tires are cold—is a subtle but meaningful way to ensure your brakes deliver their designed capability.

For the conscientious driver, there is a simple mental shift: whenever considering “brake performance,” include tire quality, age, and inflation as inseparable elements of the conversation. The system is not complete without them.

Five Exclusive Insights for Safety‑Focused Owners

For drivers who already practice diligent maintenance, these refined considerations help move beyond the basics into a more elevated standard of brake safety:

**Brake Performance Degrades Gradually—Not Just at Failure Points**

Most drivers notice brakes only when a warning light appears or a noise becomes unmistakable. Yet the system’s capability often erodes slowly: slightly longer stopping distances, marginally softer pedal feel, or subtle increases in fade after repeated stops. Treating “slightly worse than last year” as meaningful data—rather than acceptable drift—positions you to act before a crisis forces the issue.

**Precision Torque on Lug Nuts Protects More Than Wheels**

Over-tightened or unevenly tightened wheel nuts can distort brake rotors, eventually causing pedal pulsation and uneven pad contact. Insisting on torque wrenches and correct specifications during tire rotations or seasonal tire changes is not a technical nicety; it is a preventive measure against future vibration, premature rotor replacement, and compromised stopping smoothness.

**Your Driving Style Writes the Story of Your Brake Wear**

Two identical vehicles, driven with different philosophies, can show dramatically different brake outcomes at the same mileage. Anticipatory driving—lifting early, maintaining distance, and avoiding abrupt inputs—keeps temperatures lower, pads cleaner, and fluid less stressed. Over years, this style not only reduces costs; it preserves peak braking performance for the rare moments when you truly need full system capability.

**High-Quality Parts Are Not Always “Performance” Parts**

For safety-focused daily drivers, the most appropriate components often sit in the premium OEM-equivalent category, rather than in heavily marketed performance lines. Original or high-grade aftermarket pads and rotors designed to meet or exceed factory specifications typically offer better consistency, noise control, and cold performance than aggressive “track-inspired” alternatives. Quiet, linear, predictable braking is a safety asset, not merely a comfort feature.

**ABS and Stability Systems Assume a Well-Maintained Foundation**

Advanced driver-assistance systems—ABS, stability control, traction control—are calibrated on the assumption that the underlying mechanical brake system is healthy. Worn pads, contaminated fluid, or uneven hydraulic performance can force these systems to work harder or respond less effectively. Viewing electronic aids as multipliers of a sound mechanical foundation, rather than replacements for it, helps keep expectations realistic and maintenance priorities aligned.

Conclusion

Brakes are easy to take for granted precisely because they are so reliable—until they are not. For the discerning driver, brake care is less about fear and more about respect: respect for physics, for engineering, and for the lives entrusted to that modest pedal under your right foot. By listening to pedal feel, managing heat, respecting hidden vulnerabilities, honoring the role of tires, and embracing a more nuanced understanding of wear and performance, you elevate braking from a routine service item to a carefully curated safety system.

The reward is subtle but profound: a vehicle that responds with composure in the moments that matter most, and the quiet assurance that your stopping power has been treated with the same seriousness as your ability to accelerate.

Sources

- [NHTSA – Brakes: The Difference Between Stopping and Crashing](https://www.nhtsa.gov/equipment/brakes) - U.S. National Highway Traffic Safety Administration overview of brake systems and safety considerations

- [AAA – Understanding Your Car’s Braking System](https://www.ace.aaa.com/automotive/advocacy/understanding-braking-systems.html) - Clear technical explanation of modern brake components and how they work together

- [U.S. Department of Transportation – Brake Fluid Safety](https://www.transportation.gov/mission/safety) - General safety guidance and resources related to vehicle systems, including fluids and maintenance practices

- [University of Wisconsin–Madison Engineering – Brake System Fundamentals](https://www.engr.wisc.edu/) - Educational engineering resources that discuss the physics of braking and heat management (navigate via Mechanical Engineering resources)

- [Tire Rack – The Critical Role of Tires in Braking Performance](https://www.tirerack.com/tires/tiretech/techpage.jsp?techid=2) - Technical discussion of how tire condition, compound, and tread affect stopping distances

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Brake Systems.