For the driver who regards every journey as a measure of precision, brakes are not merely a safety feature—they are a standard of personal refinement. True confidence at the wheel comes from knowing that the components responsible for your final few feet of travel are cared for with intention, not neglect. This is less about reacting to a squeal or a warning light, and more about cultivating a quiet, deliberate ritual of maintenance that keeps every stop composed, predictable, and impeccably controlled.

Below, we explore a sophisticated approach to brake maintenance, built around five exclusive insights that safety‑conscious car owners rarely hear from a quick-service counter. These practices are for those who want their vehicles not just to stop, but to stop beautifully.

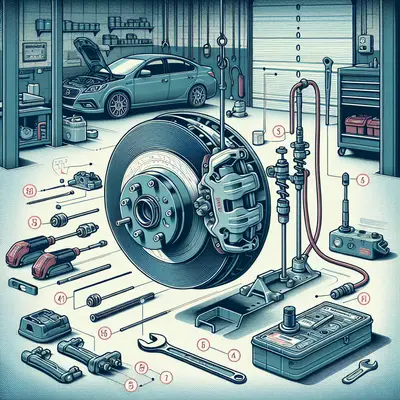

Elevating Brake Care Beyond “Pads and Rotors”

Most drivers think of brake maintenance as a simple parts swap—pads when they squeal, rotors when they pulse. A more elevated approach recognizes the brake system as a network of interdependent components that all influence pedal feel, stopping distance, and long-term reliability.

A refined brake ritual begins with an understanding of how often your driving actually demands attention. Urban, stop‑and‑go commutes and spirited highway driving can demand inspections twice as often as gentle suburban use. Visual checks of pad thickness, rotor condition, and hardware integrity at each tire rotation quietly buy you safety long before a warning sign appears. Observing the subtleties—pad wear patterns, a faint heat tint on rotors, a small lip at the rotor edge—tells an attentive owner whether the system is working in harmony or masking developing issues.

Taking maintenance beyond the basics also means tracking your service history with more nuance than a single odometer number. Recording when pads, rotors, and fluid were last replaced, under what driving conditions, and with which components transforms brake care from guesswork into informed stewardship. Over time, you will recognize your car’s unique wear rhythm and can adjust inspection intervals with the precision of a tailor perfecting a bespoke suit.

Exclusive Insight #1: The “Pedal Signature” as an Early Warning System

Every car has a distinct brake “pedal signature”: the way the pedal feels, moves, and responds when the system is in ideal condition. Sophisticated owners learn this signature and treat any deviation as valuable data, not a vague annoyance to be ignored.

A consistent, firm pedal that engages predictably halfway through its travel is typically a sign of a healthy, air‑free hydraulic system. When that pedal begins to feel slightly spongy, sinks farther toward the floor at stoplights, or responds with a subtle delay, it can signal early fluid degradation, a small leak, or the first stages of air intrusion. These changes often emerge long before fluid appears on the ground or a warning light illuminates.

Develop a habit of deliberately testing pedal feel in a controlled, safe environment—such as a quiet parking lot—after major weather shifts, long downhill drives, or heavy stop‑and‑go traffic. Press the pedal gradually and hold it: a pedal that slowly sinks is a red flag for potential master cylinder or hydraulic issues. By treating pedal feel as your first diagnostic instrument, you effectively promote comfort and control into a highly tuned safety sensor.

Exclusive Insight #2: Brake Fluid as a Precision Component, Not an Afterthought

Brake fluid is often treated as an invisible necessity—topped up if low, ignored if not. A more exacting standard recognizes brake fluid as a finely engineered medium whose condition directly governs stopping power, especially during emergency braking.

Over time, brake fluid absorbs moisture from the air, even in sealed systems. This lowers its boiling point, making it more likely to vaporize under hard or repeated braking. Vapor in the lines behaves like air, compressing under pressure and producing a soft, unreliable pedal right when you need firmness most. The result can be longer stopping distances and an unnerving lack of consistency on steep descents or during sudden stops.

Sophisticated brake maintenance includes proactively replacing brake fluid at intervals recommended by the manufacturer or even slightly sooner for vehicles driven in humid climates or hilly regions. Observing the color of the fluid—clear to light amber is ideal, dark brown is not—offers an informal indicator, but time and conditions are the true guides. For drivers who value finely tuned control, specifying a high‑quality fluid that meets or exceeds the manufacturer’s DOT rating is a subtle yet meaningful upgrade that pays dividends in predictability and pedal confidence.

Exclusive Insight #3: Heat Management as the Hidden Guardian of Brake Longevity

Most discussions of brakes focus on friction; refined brake care focuses equally on heat. Every stop converts kinetic energy into heat, and the system’s ability to manage and shed that heat quietly shapes everything from pad life to rotor integrity and fade resistance.

Attentive owners learn to interpret heat signatures on rotors. A uniform, light gray surface with evenly distributed wear usually signals proper operation. In contrast, bluish tinting, obvious dark spots, or visible surface cracks indicate that the system has been pushed beyond its comfort zone—perhaps through repeated hard braking, descending long grades in “Drive” instead of using lower gears, or driving with excessive vehicle weight. These conditions can accelerate pad glazing, rotor warping, and brake fade, even if they do not announce themselves with immediate noise.

Refined heat management involves more than mechanical parts; it also involves driving technique. Using engine braking on long descents, maintaining longer following distances to allow smoother deceleration, and avoiding unnecessary left‑foot braking minimize heat buildup. When replacing components, opting for rotors and pads engineered for your driving style—whether daily commuting, towing, or performance driving—ensures that heat is controlled rather than merely endured. Controlled heat translates directly into consistent braking feel and extended component life.

Exclusive Insight #4: The Overlooked Role of Brake Hardware and Cleanliness

Pads and rotors may take center stage, but the supporting cast—shims, clips, slide pins, and anti‑rattle hardware—often determines whether your brake system feels refined or merely functional. Neglecting these details is one of the most common reasons freshly installed brakes feel mediocre within months.

Slide pins that are improperly lubricated or partially seized prevent the caliper from moving freely, leading to uneven pad wear, pulling to one side, or subtle vibrations under braking. Corroded pad abutment surfaces and tired hardware can cause pads to bind, drag, or chatter, producing unwanted noise and heat even when the pedal is released. None of this may be evident from a quick glance through the wheel spokes.

A premium brake service should always include cleaning and refinishing contact surfaces, inspecting and, when appropriate, replacing hardware, and using the correct high‑temperature lubricants sparingly and strategically. For the owner, the insight is simple but powerful: when evaluating a shop or technician, ask how they address hardware and cleanliness, not just which pads and rotors they install. Attention to these nuances often separates a merely adequate brake job from one that feels silk‑smooth and remains quiet and consistent over time.

Exclusive Insight #5: Environmental and Seasonal Factors as Strategic Inputs

Brakes do not operate in a vacuum; their performance and longevity are quietly shaped by climate, terrain, and even regional road treatments. Recognizing how your environment affects your brakes allows you to tailor maintenance with the precision of a well‑planned itinerary rather than relying on one‑size‑fits‑all schedules.

In regions where roads are treated with salt or de‑icing chemicals, corrosion becomes a primary adversary. Calipers, backing plates, and brake lines are especially vulnerable, and external rust often precedes internal weakening. Periodic undercarriage rinsing during winter months and targeted inspections for rust bubbles on brake lines or flaking on components can prevent sudden failures that otherwise appear without warning. Coastal environments, with their salty air, can present similar challenges even without snow.

Temperature also plays a refining role. In very cold climates, pads and rotors may require a short, gentle warm‑up to deliver their best performance, while in extremely hot regions, sustained high temperatures can shorten pad life and magnify fluid degradation. For drivers who routinely tow, traverse steep grades, or drive heavily loaded vehicles, embracing shorter inspection intervals is not overcautious—it is an appropriate response to a more demanding environment. By treating climate and terrain as strategic inputs rather than background conditions, you align your brake maintenance with the realities of your road, not just the ideals of a service schedule.

Conclusion

Exquisite braking is never an accident; it is the quiet result of intentional habits, thoughtful component choices, and a willingness to notice the subtleties most drivers overlook. When you learn your car’s pedal signature, respect brake fluid as a precision component, manage heat intelligently, insist on meticulous hardware care, and adapt to your environment, you transform brake maintenance from a reactive chore into a disciplined ritual.

For the discerning driver, this is not merely about stopping in time. It is about arriving with composure, knowing that every approach to a red light, every descent, and every emergency stop is backed by a system cared for with the same refinement you bring to every other aspect of your drive. In that quiet assurance lies the true luxury of uncompromised safety.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brakes and Safety](https://www.nhtsa.gov/equipment/brakes) - Federal guidance on brake components, safety considerations, and proper maintenance practices.

- [U.S. Department of Transportation – Brake System Safety Basics (FMVSS Overview)](https://www.transportation.gov/mission/safety/brake-systems) - Explains regulatory standards and safety expectations for vehicle braking systems.

- [AAA – Car Brake System Inspection and Maintenance Tips](https://exchange.aaa.com/automotive/automotive-repair/brake-system-inspections/) - Practical recommendations on inspection intervals, warning signs, and professional service standards.

- [University of California, Berkeley – Vehicle Braking and Heat Generation (Mech. Eng. Lecture Notes)](https://www.me.berkeley.edu/sites/default/files/braking_systems_heat_generation.pdf) - Technical overview of how braking converts kinetic energy to heat and its impact on performance.

- [Continental Automotive – Brake Fluid and Braking Performance](https://www.continental-brakes.com/www/b2c/brakes_en_en/themes/brake_fluid.html) - Manufacturer‑level explanation of brake fluid properties, moisture absorption, and service intervals.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.