For drivers who expect more than “good enough” from their vehicles, brake maintenance is not a chore—it is a carefully managed standard. Beyond basic pad replacements and fluid top‑ups lies a more refined approach, one that anticipates issues before they compromise safety or driving feel. This is the realm of attentive owners who value silence over squeals, precision over guesswork, and confidence over compromise. What follows is a deeper, more exacting look at brake care designed for drivers who measure safety not by minimums, but by margins.

Redefining Maintenance: From Reactive to Proactive

Conventional maintenance focuses on fixing what is already failing. A more sophisticated approach treats brake care as an ongoing calibration of safety, comfort, and performance. That means paying attention to subtle changes—slight pedal softness, a faint vibration, a barely audible chirp—long before warning lights illuminate or distances lengthen.

Proactive brake maintenance integrates inspection into the rhythm of ownership. Every tire rotation, seasonal change, or long-trip preparation becomes an opportunity to look closer at pad thickness, rotor condition, and fluid quality. This mindset transforms the brake system from a hidden, forgotten component into a deliberately managed safety instrument.

For the discerning driver, the goal is not just to restore function when something goes wrong; it is to preserve a consistent, predictable braking experience over the life of the car. That consistency is the hallmark of a truly well-maintained vehicle.

Understanding the System: Seeing Beyond Pads and Rotors

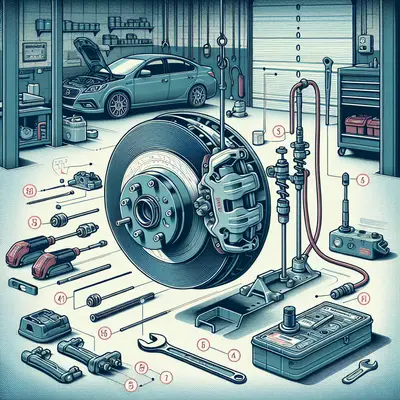

A refined brake maintenance standard begins with understanding that the brake system is an integrated network, not a collection of isolated parts. Pads and rotors may be the most visible components, but they are only the final link in a chain that includes calipers, hoses, master cylinder, ABS/ESC modules, and the brake fluid itself.

Even a minor deficiency in one element can subtly degrade the entire system. A slightly sticky caliper can cause uneven pad wear and heat spots on the rotor. Age-hardened rubber brake hoses can expand under pressure, creating a softer pedal feel even when pads and rotors look pristine. Brake fluid that has absorbed moisture can lower the boiling point, quietly eroding your margin of safety during sustained or emergency braking.

Approaching maintenance with this systems view changes the service conversation. Instead of asking, “Do I need new pads?” the more sophisticated question becomes, “Is my entire braking system performing as a coherent, predictable whole?” That is the standard that separates routine care from elevated maintenance.

Five Exclusive Insights for Elevated Brake Safety

The following insights move beyond generic advice and into the subtleties that genuinely matter to owners who prioritize exceptional brake safety and refinement.

1. Treat Brake Feel as a Diagnostic Instrument

Most drivers notice only extremes: a grinding noise or a warning light. The discerning driver learns to interpret brake feel the way a pilot reads instruments.

Subtle changes in pedal travel, initial bite, and modulation can reveal issues long before they become urgent. A gradually lengthening pedal stroke may indicate minor air intrusion or early internal wear in the master cylinder. A slightly delayed, “mushy” response, especially after repeated braking, can point to moisture-laden fluid approaching its limits. A pedal that feels inconsistent from one day to the next may suggest temperature-sensitive components, such as marginal pads or partially seized slide pins.

Make it a habit to assess brake feel in controlled, predictable conditions: level road, steady speed, no distractions. Note how the pedal responds in the first inch of travel, under moderate pressure, and in a firm but non-emergency stop. Those impressions, tracked over time, become one of the most sophisticated diagnostic tools a driver possesses.

2. Insist on System-Level Service, Not Just Parts Replacement

A premium brake service is defined not only by the quality of parts used but by the completeness of the procedure. Two cars can leave a shop with “new pads and rotors,” yet one will stop with silent, glass‑smooth authority while the other shudders and squeals after a few weeks.

A system-level brake service should include:

- Careful cleaning and lubrication of caliper slide pins with high‑temperature brake lubricant

- Inspection of caliper pistons and dust boots for sticking, cracking, or contamination

- Proper preparation of rotor surfaces (or replacement, not just resurfacing, where appropriate)

- Correct torque and tightening sequence on wheel lug nuts to prevent rotor distortion

- Verification of brake fluid condition, with a scheduled flush when due

This comprehensive approach not only enhances safety but preserves the refined pedal feel and noise-free operation that discerning owners expect. When discussing service with a shop, the most telling question is not “What will you replace?” but “What will you inspect, clean, measure, and verify?”

3. Elevate Brake Fluid from Afterthought to Priority

Brake fluid is arguably the most underappreciated component of the braking system. It is hygroscopic—designed to absorb moisture from the atmosphere—which is vital for preventing localized corrosion but gradually lowers its boiling point. Over time, this can lead to vapor formation under heavy braking, producing a soft pedal or temporary loss of stopping power.

Drivers in humid climates, high-altitude regions, or who regularly descend long grades have even more reason to treat fluid quality seriously. A refined maintenance regime respects the manufacturer’s interval as a minimum, not a target, and often opts for more frequent fluid changes to maintain a generous safety margin.

For the safety-conscious owner, two practices are particularly valuable:

- Request a documented brake fluid change history and, when possible, a boiling-point or moisture-content test.

- Consider higher‑performance fluids (that still meet manufacturer specifications) if the vehicle regularly encounters demanding conditions, such as towing or mountain driving.

Brake fluid is invisible in daily use, but its condition is central to maintaining consistent, confidence-inspiring braking—especially in the moments that matter most.

4. Use Driving Environment to Shape Your Maintenance Rhythm

Not all mileage is equal. A vehicle that accrues 20,000 miles a year in stop‑and‑go urban driving demands a very different brake maintenance cadence from one that covers the same distance on open highways.

Sophisticated brake care takes into account:

- **Urban & stop‑start driving:** Higher brake temperatures, more frequent applications, and accelerated pad wear. Expect shorter intervals between inspections and replacements.

- **Mountain or hilly regions:** Extended downhill braking increases the risk of fade and rotor heat stress, making fluid condition and rotor integrity paramount.

- **Coastal or high‑humidity climates:** Increased likelihood of corrosion on calipers, rotors, and lines. More frequent inspections for rust, sticking components, or pitted surfaces are essential.

- **Infrequent use or seasonal storage:** Cars that sit for long periods can develop surface rust on rotors and sticking calipers; gentle but deliberate braking after storage helps restore clean contact surfaces.

By aligning maintenance with environment and usage, you avoid both under‑servicing (risking safety) and unnecessary, poorly timed work. The result is a tailored brake care rhythm that respects how and where you actually drive.

5. Align Component Quality with Your Safety Expectations

For drivers who hold their vehicles to a higher standard, the choice of brake components is more than a budget decision—it is a statement of priorities. Not all pads, rotors, and hardware are engineered to the same expectations of refinement, durability, and performance.

Considerations for the safety‑focused, refinement‑oriented owner include:

- **Pad formulation:** Premium ceramic or high‑quality low‑metallic pads often provide quieter operation, less dust, and better consistency, though performance under extreme heat may vary by brand.

- **Rotor design and metallurgy:** Quality rotors with precise machining help reduce pulsation, noise, and premature warping. Slotted or drilled rotors may be beneficial for heavy use, but they must be selected carefully to match the vehicle’s needs and manufacturer guidance.

- **Hardware kits:** New clips, shims, and anti-rattle components are essential for quiet, stable performance and should not be treated as optional extras.

Investing in higher‑grade components is not about overbuilding the system; it is about aligning the vehicle’s braking character with the driver’s expectations: silent, predictable, and authoritative, time after time.

Integrating Brake Care into a Refined Ownership Experience

For the discerning driver, elevated brake maintenance is less about occasional heroics and more about quiet, consistent attentiveness. It is the willingness to notice small changes and to treat them as early signals rather than inconveniences. It is the insistence on system-level service, documented work, and parts whose quality matches the value of the vehicle and its occupants.

This mindset transforms brake care from a reactive, invoice-driven experience into a curated element of ownership—no less important than premium fuel, thoughtful detailing, or careful tire selection. In an era of increasingly sophisticated vehicles and dense traffic environments, refined brake maintenance is not a luxury; it is a calm, deliberate safeguard.

The reward is not only shorter stopping distances, but a deeper, more enduring confidence every time your foot meets the pedal.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brakes](https://www.nhtsa.gov/equipment/brakes) – Federal guidance on brake safety, component function, and related regulations

- [U.S. Department of Transportation – Brake Fluid Safety](https://www.transportation.gov/mission/safety) – General safety information and policy context for vehicle systems, including braking and fluids

- [AAA – How to Know When You Need Brake Service](https://www.aaa.com/autorepair/articles/how-to-know-when-you-need-brake-service) – Practical insight into brake wear signs, service intervals, and inspection practices

- [Consumer Reports – Car Brakes: A Guide to Brake Maintenance](https://www.consumerreports.org/cars/car-maintenance/car-brakes-a-guide-to-brake-maintenance-a1189434759/) – Independent guidance on brake components, expected lifespans, and servicing considerations

- [Penn State Extension – Hydraulic Brake Systems and Fluids](https://extension.psu.edu/hydraulic-brake-systems-and-fluids) – Technical explanation of hydraulic brake systems and the importance of brake fluid characteristics

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.