For drivers who treat safety as a standard rather than a selling point, brake care belongs in a higher category of attention. It is not simply about preventing failure; it is about preserving the refined control, silence, and composure that distinguish a well‑kept vehicle from a merely functional one. Thoughtful brake maintenance turns every stop into a quiet, deliberate act of confidence.

Elevating Brake Maintenance Beyond the “Wear and Tear” Mindset

Most owners think of brakes only when something feels wrong—noise, vibration, or a dash light that can no longer be ignored. A more sophisticated approach treats the brake system as a curated ensemble of components that must age together gracefully. Pads, rotors, fluid, hoses, hardware, and even wheel bearings interact continuously; neglect in any one area subtly degrades the whole.

This perspective reframes maintenance from reactive repair to proactive refinement. Instead of asking, “How long can I wait?” the discerning driver asks, “How consistently can I maintain peak performance?” This shift has tangible benefits: shorter stopping distances, quieter operation, more predictable pedal feel, and ultimately, a wider margin for error when it matters most. The result is not only safety, but also a driving experience that feels composed rather than compromised.

Precision in Pad Selection: Matching Material to Driving Character

Brake pads are often reduced to price points—“budget,” “mid‑grade,” or “premium.” A more refined approach recognizes pad material as a tuning tool, much like tires or suspension. Ceramic, semi‑metallic, and organic formulations each impart a distinct character to your braking.

Ceramic pads generally offer quieter operation and lower dust, suitable for luxury sedans and daily drivers where refinement is prized. Semi‑metallic pads provide strong bite and heat resistance, often preferred for spirited driving, heavier vehicles, or frequent highway use. Organic pads, while less common in modern applications, can offer a softer, more progressive feel in specific scenarios.

The exclusive insight here is to choose pad material not only by manufacturer recommendation, but also by your driving environment: stop‑and‑go urban traffic, steep hills, high‑speed interstates, or mixed conditions. Consult your owner’s manual, then compare it with the pad manufacturer’s technical data, not just marketing copy. When pads align with your usage, you reduce noise, uneven wear, and glazing—subtle faults that compromise both comfort and control long before outright failure occurs.

Exclusive Insight #1: Treat pad choice as a fine‑tuning decision, not an afterthought. Matching pad compound to your real driving habits refines quietness, pedal feel, and emergency stopping capability in ways generic “premium” labels cannot.

The Underrated Fluid Strategy: Thinking in Terms of Temperature, Not Time

Brake fluid is typically discussed in intervals—“every two years” or “at major service.” A more advanced view considers operating temperature and humidity as the decisive factors. Brake fluid is hygroscopic: it absorbs moisture over time, which lowers its boiling point and increases internal corrosion.

Repeated hard braking (mountain driving, towing, high‑speed commuting) raises brake temperatures and pushes fluid closer to its thermal limits. Even if you drive modest annual mileage, a few demanding trips can degrade fluid far more than the calendar suggests. Conversely, a gently driven, garaged vehicle in a dry climate may not deteriorate as quickly.

Rather than relying solely on mileage or age, pay attention to your usage profile and consider periodic testing of fluid boiling point at a reputable shop. When in doubt, a complete flush is an inexpensive form of insurance that protects ABS valves, calipers, and master cylinders—components that are far more costly and inconvenient to replace.

Exclusive Insight #2: Think of brake fluid in terms of heat cycles and climate, not just years. Drivers who tow, descend steep grades, or brake aggressively should treat fluid flushes as a performance safeguard, not a routine line item.

Rotor Care as a Craft: Surface Quality, Not Just Thickness

Rotors are often judged solely on thickness and run‑out—if they meet minimum specifications, they are deemed “fine.” Yet a truly composed braking experience depends on the quality of the rotor surface and how it interacts with the pad material. Even when thickness is adequate, heat spots, glazing, and uneven pad deposits can produce judder, noise, or slight inconsistencies in pedal feel.

The sophisticated owner pays attention to the story rotors tell: blue discoloration signals heat stress; fine cracks near drilled holes (on performance rotors) hint at fatigue; ridging or uneven sheen suggests imbalance in pad contact. When replacing pads, it is often wiser to invest in quality rotors matched to the pads than to salvage worn discs with minimal resurfacing.

Equally important is proper bedding‑in of new pads and rotors. A careful series of moderate stops from increasing speeds establishes an even transfer layer of pad material on the rotor face, promoting consistent friction and reducing the chance of pulsation. This is not merely a performance trick; it is a refinement practice that rewards patience with smoother, quieter operation for tens of thousands of miles.

Exclusive Insight #3: Treat rotors as precision surfaces that must be carefully paired and bedded with pads. Paying attention to heat marks, deposits, and bedding procedure elevates stopping quality beyond basic compliance.

Beyond the Wheels: Inspecting the Hidden Architecture of Safety

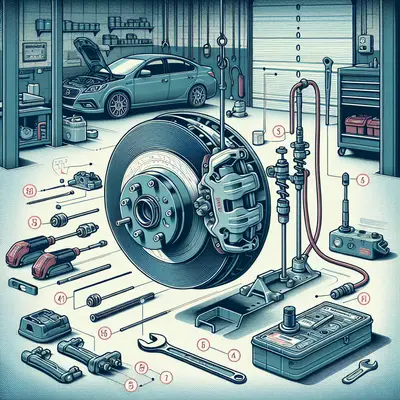

For many drivers, brake inspection ends at the caliper, pad, and rotor visible behind the wheel spokes. A more comprehensive, premium maintenance philosophy extends to the unseen architecture that supports every stop: hoses, lines, slide pins, hardware, and mounting points.

Rubber brake hoses can swell internally without obvious external cracks, leading to delayed release or uneven braking. Steel lines may corrode stealthily along brackets and underbody seams, especially in regions where road salt is common. Caliper slide pins and pad abutment clips, when neglected, can cause one‑sided wear, pulling, or dragging. Even wheel bearings and hub assemblies influence braking symmetry and stability.

A high‑quality service appointment should include a methodical inspection of these components, not just a cursory glance at pad thickness. Ask specifically about hose condition, line corrosion, caliper hardware lubrication, and the state of dust boots and seals. This is where a modest investment in preventive replacement—of aging hoses or heavily corroded lines—can prevent abrupt, system‑level failures that no dashboard light will politely announce in advance.

Exclusive Insight #4: Extend your brake checklist to include hoses, lines, and hardware as critical safety elements, not miscellaneous extras. The most consequential problems often emerge where owners rarely look.

Calibrated Habits: Driving Techniques That Protect Brake Sophistication

Even the best‑maintained brake system can be undermined by harsh or inattentive driving habits. A refined driver recognizes that technique is a powerful form of maintenance. Smooth, anticipatory braking reduces peak temperatures, slows pad and rotor wear, and keeps fluid from routinely approaching its boiling point.

This does not mean timid driving; it means calibrated inputs. Looking further ahead, easing off the throttle earlier, and applying progressive pressure instead of abrupt stabs all contribute to cooler, more consistent operation. On long descents, this habit extends to using engine braking (downshifting in an automatic or manual within safe RPM limits) to share the workload with the drivetrain instead of relying solely on the pads.

Parking practices matter, too. Regularly engaging the parking brake (where appropriate and according to the vehicle’s design) helps keep rear mechanisms moving freely, especially on disc‑plus‑drum or integrated drum‑in‑hat parking systems. In regions with cold, wet climates, occasionally driving a bit longer after heavy rain or car washes allows the brakes to warm slightly, discouraging rust buildup on rotors.

Exclusive Insight #5: Consider driving style an integral part of your brake maintenance plan. Anticipatory braking, proper use of engine braking, and mindful parking habits protect the system’s composure as much as any part replacement.

Conclusion

Brake maintenance, approached with discernment, becomes something more than a response to squeals and warning lights. It evolves into a quiet discipline of matching materials to driving style, managing heat with intention, respecting rotor surfaces, scrutinizing hidden components, and refining daily driving habits.

For the driver who values not only safety but also the serene confidence of a vehicle that responds precisely under pressure, these practices form a personal manifesto. Every well‑planned service, every thoughtful part choice, and every measured press of the pedal adds up to something rare on today’s roads: not just the ability to stop, but the assurance of stopping well.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brake Safety Overview](https://www.nhtsa.gov/equipment/brakes) - Authoritative guidance on brake system safety, components, and recalls

- [Federal Motor Carrier Safety Administration (FMCSA) – Brake Safety Resources](https://www.fmcsa.dot.gov/brake-safety) - Offers technical insights on brake inspections, performance, and safe operation under demanding conditions

- [AAA – Understanding Your Car’s Braking System](https://exchange.aaa.com/automotive/understanding-your-cars-braking-system/) - Clear explanations of how brake systems work and recommended maintenance practices

- [U.S. Department of Energy – Driving More Efficiently](https://www.energy.gov/energysaver/driving-more-efficiently) - Describes driving habits (like smoother braking and anticipatory driving) that reduce wear and improve vehicle efficiency

- [University of California, Berkeley – Brake System Fundamentals (Mechanical Engineering Course Notes)](https://me.berkeley.edu) - Provides foundational engineering context for how braking forces, heat, and materials interact (navigate via departmental course materials)

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.