For drivers who expect more than mere functionality from their vehicles, brake care is not a chore—it is a discipline. A well‑maintained brake system transforms every stop into a quiet confirmation that your standards have been met. This guide focuses on a more refined approach to brake maintenance: subtle checks, elevated habits, and five exclusive insights that speak directly to owners who view safety as non‑negotiable.

Understanding Brake Maintenance as a Precision Practice

Most drivers think of brake maintenance only when pads are worn or a warning light appears. Discerning owners, however, understand that brake care begins long before obvious symptoms emerge. Brakes are a system, not a single part: pads, rotors, calipers, hoses, brake fluid, ABS modules, and even tires contribute to stopping performance.

Treating brake maintenance as a precision practice means valuing consistency over crisis response. Routine inspections, fluid checks, and listening for early cues allow you to address minor issues before they mature into costly or dangerous failures. This mindset also extends to who works on your brakes: skilled technicians using quality components and proper torque procedures are central to preserving both safety and driving refinement.

Ultimately, a cultivated brake care routine is about removing uncertainty. When each stop feels linear, predictable, and quietly authoritative, you know your attention to detail is paying dividends.

The Foundation: What an Elevated Brake Service Should Include

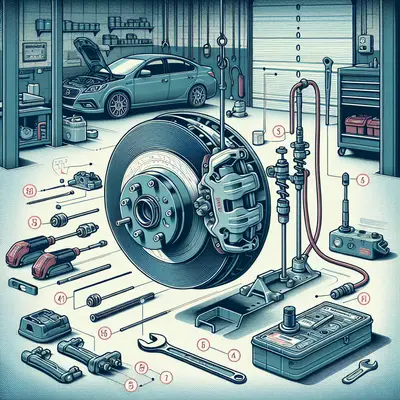

A premium brake service is more than simply replacing pads. It is a thorough evaluation and refresh of the entire system. At minimum, a high‑standard brake service should include measurement of pad thickness, rotor condition (thickness, runout, and surface quality), and visual inspection of calipers, hoses, and hardware.

Caliper slide pins should be cleaned and lubricated with the correct high‑temperature grease to prevent binding and uneven pad wear. Contact points where pads sit in the bracket should be de‑rusted and treated appropriately so pads move freely and retract properly. The technician should evaluate brake fluid condition, checking both level and contamination, and recommend replacement if the fluid is dark or moisture content is elevated.

A refined service also involves confirming proper torque on wheel fasteners—overtightening can distort rotors and create pulsation during braking. Test driving after service is essential, not just to ensure function, but to verify pedal feel, ABS operation, and noise characteristics. When done correctly, the result is a braking system that feels composed, confident, and consistent in a variety of conditions.

Five Exclusive Insights for Owners Who Refuse to Compromise

For owners who treat safety and control as central to their driving experience, the following five insights add a layer of sophistication to routine brake care.

1. Brake Feel Is a Diagnostic Tool—Treat It as a Baseline

Most drivers ignore brake pedal feel unless it changes dramatically. A more exacting approach is to treat current brake feel as a reference point and remain alert to subtle differences. A progressively softer pedal, a slightly longer stopping distance, or a faint vibration under light braking are early warnings, not inconveniences.

Develop the habit of occasionally performing a controlled, firm stop on an empty, straight road. Note how quickly the vehicle decelerates, how the pedal responds, and whether the vehicle tracks straight. Document your impressions mentally or in a maintenance journal. Over time, you will detect small deviations that often precede leaks, air in the system, rotor irregularities, or pad glazing—long before a warning light appears.

2. Brake Fluid Aging Is Measured in Moisture, Not Just Time

Brake fluid is frequently overlooked because it is out of sight. Yet it is one of the most critical elements of consistent, confident braking. Most modern brake fluids (DOT 3, 4, and some 5.1) are hygroscopic: they absorb moisture from the atmosphere over time. This lowers their boiling point and increases internal corrosion risk.

While many manufacturers suggest replacement every 2–3 years, a more refined approach accounts for climate and usage. In humid regions or for vehicles driven frequently in traffic or on mountain roads, brake fluid can degrade faster. A service facility with the right equipment can measure the fluid’s boiling point or moisture content to inform decision‑making rather than relying solely on the calendar. Replacing fluid before it becomes marginal preserves pedal firmness during hard stops and helps protect ABS modules, calipers, and lines from premature corrosion.

3. Rotor Quality and Finish Quietly Define Your Stopping Character

Rotors are often treated as generic components, but their quality and finishing significantly influence braking refinement. Lower‑grade rotors may meet minimum dimensions but lack precise balance or uniform hardness, leading to noise, pulsation, or quicker warping under heat.

For drivers who value smooth, silent stops, insist on rotors from reputable manufacturers that meet or exceed OEM specifications. The rotor surface finish should be clean, consistently machined, and free of shipping oils before installation. After installation, a proper bedding‑in procedure—controlled stops from moderate speed, allowing cooling between applications—mates pads and rotors evenly. This reduces the likelihood of uneven pad deposits, which are a common cause of pedal vibration misdiagnosed as “warped” rotors.

4. Your Driving Style Is Part of Your Maintenance Plan

How you use your brakes determines how you should maintain them. Urban stop‑and‑go driving, frequent downhill journeys, spirited driving, and towing all accelerate wear and heat‑stress the system. Under these conditions, pads and rotors may benefit from higher‑temperature‑rated friction materials designed for heavier use, rather than basic entry‑level components.

Thoughtful driving habits—earlier deceleration, using engine braking on declines, and avoiding late, aggressive stops when unnecessary—do more than improve comfort; they manage heat, the primary enemy of braking consistency. Less heat means less likelihood of fluid boil, pad glazing, and rotor damage. For the driver with high expectations, adapting both component selection and technique to real‑world use is a subtle but powerful form of maintenance.

5. Cleanliness and Hardware Are the Hidden Guardians of Quiet Brakes

Noise is often dismissed as a mere annoyance, but to a discerning driver it indicates something out of tune. Many squeaks and rattles originate from overlooked details: corroded pad brackets, missing or worn anti‑rattle clips, low‑quality shims, or contamination at the pad–rotor interface.

During service, request that the technician remove rust scale from pad abutment areas, replace hardware (clips, springs, and boots) rather than reusing tired pieces, and avoid getting lubricant on pad surfaces or rotors. Quality anti‑squeal compounds, when used sparingly and correctly behind the pad backing plate, help damp vibration without masking mechanical flaws. A brake system that is both quiet and responsive is rarely an accident; it is the product of meticulous attention to the smallest components.

Integrating Brake Care into a Complete Safety Strategy

Brakes do not operate in isolation, and a genuinely elevated maintenance philosophy considers the entire safety ecosystem of the vehicle. Tires, for example, are as critical as pads and rotors. Even a perfectly maintained brake system cannot overcome worn, underinflated, or improperly matched tires, especially in wet or cold conditions. Regular tire rotation, alignment, and pressure checks are indirect but essential contributions to braking performance.

Similarly, suspension components—struts, shocks, bushings—affect how effectively the vehicle remains stable during hard stops. A car that pitches excessively or feels unsettled under braking may need suspension attention, not just fresh pads. Modern stability control and ABS systems also rely on clean wheel speed sensors and sound wiring. Having these checked during major services guards against intermittent or hidden issues that might only appear in an emergency.

By framing brake maintenance as part of a holistic vehicle safety strategy, you transform routine service into a curated program of assurance. The goal is not simply passing an inspection, but ensuring that every deceleration—from a gentle glide to a full‑force stop—reflects the same standard of care you expect from the rest of your life.

Conclusion

Refined brake maintenance is not about extravagance; it is about intention. When you treat your braking system as a precision instrument rather than a disposable part, you gain more than quiet operation and longer component life—you gain confidence. Subtle habits, elevated component choices, and an informed relationship with your technician create a safety margin that is both tangible and deeply reassuring.

Each stop becomes a quiet confirmation that you have done more than the minimum. You have curated your own standard of safety—and your brakes respond in kind.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brake Safety](https://www.nhtsa.gov/equipment/brakes) - Federal guidance on brake systems, safety considerations, and component performance

- [U.S. Department of Transportation – Brake Fluid Safety Information](https://www.transportation.gov/content/brake-fluid) - Explains brake fluid properties, moisture absorption, and maintenance recommendations

- [Society of Automotive Engineers (SAE) – Brake System Technical Papers](https://www.sae.org/search/?qt=brake%20system) - Research and engineering insights on brake performance, materials, and system design

- [AAA – Vehicle Braking System Basics](https://exchange.aaa.com/automotive/automotive-testing-and-research/how-your-vehicles-braking-system-works/) - Overview of brake system components and how they work together in everyday driving

- [Bridgestone – How Tires Affect Braking Distance](https://www.bridgestonetire.com/learn/maintenance/tire-maintenance/tire-traction-and-braking-distance/) - Explores the relationship between tire condition and braking performance

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.