For drivers who take pride in impeccable control, brakes are not merely components—they are the final word in authority on the road. True confidence at the pedal does not come from last-minute repairs, but from a disciplined, almost curatorial approach to maintenance. This is not about fear or over-caution; it is about driving with the composed certainty that every stop has been rehearsed by meticulous care long before the light turns red.

Below, you’ll find a refined, safety‑first approach to brake maintenance, anchored in five exclusive insights that reward attentiveness, precision, and a refusal to settle for “good enough.”

Understanding Modern Brake Systems with a Curated Eye

Today’s brake systems blend mechanical hardware with sophisticated electronics. For the discerning owner, this complexity is not a nuisance—it is an opportunity to manage safety with the same intentionality you bring to your vehicle’s performance and appearance.

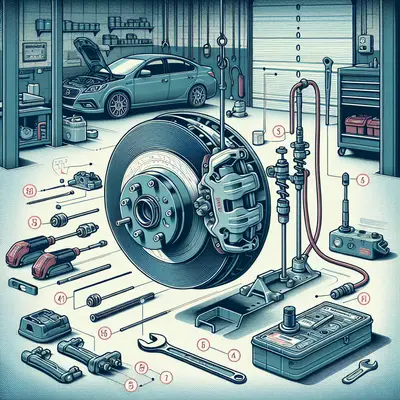

Disc brakes, calipers, pads, rotors, hydraulic lines, ABS modules, and electronic brake distribution systems all participate in every stop. Each component has a wear pattern and a story to tell. A rotor’s subtle lip, a pad’s glazing, or a slightly discolored brake line are not trivial details; they are early signals about heat, pressure, and longevity. When you view the system as a cohesive ensemble rather than isolated parts, maintenance becomes less reactive and more akin to ongoing calibration.

Maintaining this ensemble begins with schedule discipline—observing the manufacturer’s inspection intervals, not as suggestions, but as the framework for your own, more exacting standard. The goal is simple: ensure that every braking event feels unremarkable, because your system is never allowed to drift into “almost fine.”

Exclusive Insight #1: Reading Road Dust Like a Diagnostic Report

Most drivers treat brake dust as a cosmetic inconvenience. A more discerning approach treats it as data.

Brake dust color, texture, and quantity can signal the health of your pads, rotors, and even your driving style. Fine, dark dust that accumulates quickly on the front wheels often indicates soft, aggressive pads doing significant work—common in performance setups or heavy stop‑and‑go usage. A sudden decrease in visible dust, on the other hand, can be an early indicator of pad glazing (overheating that hardens the pad surface), leading to diminished friction and longer stopping distances.

Uneven dust between the left and right wheels can signal a sticking caliper, imbalanced pad wear, or a hydraulic issue. Excessive metallic flecks in the dust may suggest that pads are worn down to the backing plate, now scoring the rotors—long before you hear the warning squeal.

Treat your wheels as the first “inspection window” of your brake system. When you or your detailer clean the vehicle, a deliberate glance at dust patterns can function as an elegant, non-invasive early warning system.

Exclusive Insight #2: Heat Management as a Luxury, Not a Luxury Option

Brake performance is, at its core, heat management. Every time you slow the vehicle, kinetic energy is transformed into heat at the rotor and pad surface. The more gracefully your system manages that heat, the more consistent and predictable your stopping becomes.

High‑quality rotors and pads are not simply “premium” by marketing—they often feature better metallurgy, slots or vents designed for cooling and gas evacuation, and friction materials tuned for temperature stability. For spirited or heavy urban driving, this is not an indulgence; it is a logical extension of safety.

Your own driving habits are part of this temperature equation. Repeated hard stops from high speeds, riding the brakes on long descents instead of downshifting, or late, abrupt braking at lights all push the system toward thermal fatigue. Overheated pads can glaze, rotors can warp or develop hard spots, and fluid can approach boiling, softening pedal feel.

A refined brake routine favors anticipatory driving: easing off earlier, using engine braking on long grades, and allowing the system to cool between aggressive stops when possible. Think of it as thermal stewardship—protecting your components so that when you truly need maximum braking, the system is fresh, cool enough, and fully capable.

Exclusive Insight #3: Brake Fluid as the Hidden Guardian of Pedal Feel

Brake fluid is one of the most neglected elements of vehicle maintenance, yet it directly influences braking precision. Over time, brake fluid absorbs moisture from the atmosphere, even in “sealed” systems. This lowers the fluid’s boiling point and increases internal corrosion risk.

For a driver who values unflinching consistency, waiting until fluid is “dark” or “dirty” is far too casual. A proactive standard is to adhere to the manufacturer’s change interval, and when in doubt, favor the shorter end of the range—often every two to three years, or sooner for vehicles that experience heavy braking or live in humid climates.

High‑quality fluids, especially those meeting or exceeding DOT specifications for your vehicle, offer more predictable performance under repeated heavy stops. The reward is subtle but unmistakable: a firm, confidence‑inspiring pedal, less fade over time, and a system whose internal components—calipers, master cylinder, ABS pump—enjoy a longer, healthier service life.

Savvy owners also ensure that fluid changes are performed by technicians who understand the nuances of ABS and electronic brake distribution systems, using correct bleeding procedures to avoid trapped air and preserve electronic module integrity.

Exclusive Insight #4: The Value of Symmetry in Pad and Rotor Replacement

A sophisticated approach to brake service recognizes that the system works in pairs and patterns. Replacing a single pad, single rotor, or only one side of an axle may seem economical, but it can subtly destabilize braking behavior.

Ideal practice is to replace pads and rotors in matched sets by axle—both fronts or both rears—maintaining symmetry in friction, thickness, and wear characteristics. This symmetry supports stable braking in emergency maneuvers, reduces vibration and noise, and ensures that electronic stability and ABS systems can operate with balanced, predictable inputs.

Additionally, pairing new pads with properly resurfaced or new rotors minimizes break‑in irregularities and reduces the likelihood of uneven deposits that can masquerade as “warped” rotors. Taking the time to perform a proper bedding‑in process—smooth, progressively firm stops from moderate speeds to evenly transfer material onto the rotor surface—further refines braking feel and longevity.

This philosophy extends to hardware: premium shims, anti‑rattle clips, and high‑temperature brake lubricants are not afterthoughts; they are finishing details that transform a basic repair into a meticulously executed system reset.

Exclusive Insight #5: Quiet and Vibration as Your Early Warning System

The most advanced drivers listen to their brakes long before they “fail.” Noise and vibration are among the earliest forms of feedback, provided you know how to interpret them.

A light, rhythmic squeal at low speeds may reflect pad composition, glazing, or hardware fatigue—not yet an emergency, but certainly a prompt to inspect before performance degrades. A harsher grinding noise usually indicates metal-to-metal contact and demands immediate attention; by the time this sound appears, damage to rotors is often already underway.

Steering wheel vibration under braking, especially from highway speeds, may signal rotor thickness variation, uneven pad deposits, or loose suspension and steering components that affect brake behavior. A pulsating pedal can point to ABS engagement on compromised surfaces, but when it occurs on dry, predictable pavement, it is often a sign of rotor irregularities.

Treat these sensations as an invitation, not an annoyance. Arranging a professional inspection at the first sign of new noise or feel change is an elegant, preventative act—one that protects both your safety margin and the integrity of your high‑value components.

Crafting a Personal Brake Maintenance Standard

Owning a vehicle that stops with composure and quiet authority is not about anxiety; it is about standards. Brake maintenance, approached thoughtfully, becomes less of a chore and more of an ongoing dialogue with the car—subtle signals traded for confident responses.

Keeping a dedicated maintenance record, partnering with a shop that respects OEM specifications and quality components, and integrating simple visual checks into your routine (wheels, fluid level, driveway drips, pedal feel) turn you into the curator of your own safety. The goal is not merely to avoid failure, but to ensure that every stop—whether from 20 mph in a parking garage or 70 mph on a wet highway—feels effortless, predictable, and quietly assured.

In a world full of distractions and hurried shortcuts, a meticulously maintained brake system is a quiet luxury with profound consequences. You may never need the full extent of its capability—but if you do, you will be grateful you treated it as non‑negotiable.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brakes and Safety](https://www.nhtsa.gov/equipment/brakes) – Overview of brake safety, performance expectations, and regulatory context

- [U.S. Department of Energy – Vehicle Maintenance: Brakes](https://afdc.energy.gov/conserve/behavior_maintenance.html) – Discusses how maintenance practices, including braking, affect efficiency and safety

- [Bridgestone – How Brakes Work and When to Service Them](https://www.bridgestonetire.com/learn/maintenance/how-do-car-brakes-work/) – Clear technical explanations of brake system components and service indicators

- [Brembo – Tech Insights on Brake Discs and Pads](https://www.brembo.com/en/company/news/brembo-brake-discs-and-pads) – In‑depth information on materials, heat management, and performance considerations for premium systems

- [Penn State University – Brake Fluid and Hydraulic Systems Basics](https://www.psu.edu/news/engineering/story/how-brakes-work/) – Educational overview of hydraulic brake operation and the role of brake fluid

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.