Every truly composed drive begins long before you press the pedal. It starts with a brake system that has been maintained with intention, precision, and respect for the physics at play beneath the vehicle’s polished exterior. For drivers who value refinement, brake care is not a reaction to squeals and warning lights; it is a quiet standard upheld long before urgency arrives.

This guide explores a more elevated approach to brake maintenance—one that blends technical understanding with discerning attention to detail. Along the way, you’ll find five exclusive insights that safety‑conscious owners can use to move beyond “good enough” and toward truly exceptional brake confidence.

---

Understanding Brake Maintenance as a Performance Discipline

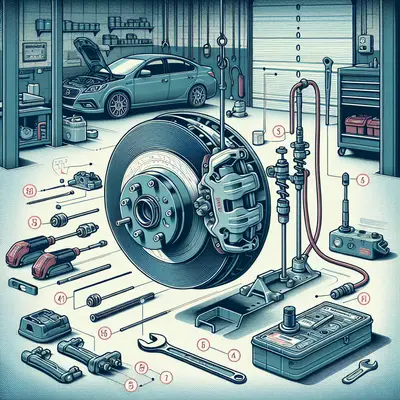

Brake maintenance is often framed as a basic safety requirement, but for the attentive owner, it is closer to a performance discipline. Each component—pads, rotors, calipers, brake fluid, lines, and hardware—contributes to the car’s ability to deliver repeatable, controlled deceleration in a wide range of conditions. It is not simply about stopping; it is about stopping predictably every time, whether on a hot downhill descent, a wet city street, or during an unexpected emergency maneuver.

Recognizing brake maintenance as a performance discipline encourages earlier intervention and higher standards. Rather than waiting for the system to complain—via pulsations, noises, or warning icons—the refined driver uses inspection intervals as non‑negotiable appointments. This mindset brings the braking system onto the same level of care as engine service or tire choice. With that elevated framework in mind, the following sections examine how to maintain brakes with a premium, detail‑driven approach.

---

The Foundation: Consistent, Intelligent Inspection

Sophisticated brake care begins with a structured inspection rhythm. While many manufacturers suggest inspection intervals aligned with oil changes or annual services, discerning owners tend to adopt a more intentional schedule—especially for vehicles driven in heavy traffic, mountainous regions, or high‑temperature climates.

A comprehensive inspection looks beyond simple pad thickness. A trained eye evaluates rotor surface condition, caliper slide freedom, dust boot integrity, brake line corrosion, and even the evenness of pad wear across each axle. Subtle taper wear on pads, light scoring on rotors, or a slightly stiff caliper guide pin may not yet trigger a symptom, but they quietly forecast future issues. Catching these signs early allows for targeted maintenance—such as cleaning and lubricating slides, de‑rusting contact points, or resurfacing rotors within specification—rather than waiting for a full system overhaul.

For the owner, the hallmark of a well‑managed brake inspection is documentation. Retaining service records, measurements, and comments on component condition transforms maintenance from guesswork into a traceable history. Over time, this creates a pattern: how long pads typically last in your driving environment, how rotors wear, and how quickly brake fluid degrades. That historical clarity is invaluable when deciding between repair options or considering upgrades.

---

Premium Detail: Selecting Brake Parts That Match Your Driving Profile

Not all brake components are created equal, and a premium maintenance strategy acknowledges that the “correct” part has as much to do with driving style and environment as with the car’s badge. While original equipment (OE) parts are usually a safe benchmark, sophisticated owners often evaluate alternatives within reputable brands to better match their specific needs.

For predominantly urban driving with frequent, light-to-moderate stops, low-dust, noise-optimized pads paired with high-quality rotors offer a clean, quiet experience. Those regularly descending long grades or carrying heavier loads may benefit from pads engineered for higher heat resistance and rotors designed to dissipate heat efficiently. Climate matters too: areas with road salt and moisture can justify coated rotors and stainless or corrosion-resistant hardware to preserve performance over time.

An elevated approach to parts selection goes beyond the label on the box. It includes asking for (or reviewing) friction ratings, rotor metallurgy quality, and the warranty or testing standards behind the product. Choosing from reputable suppliers and avoiding ultra-budget components reduces the risk of inconsistent friction, premature warping, or undesirable noise. The result is not merely a “new” brake system, but a system tuned to your expectations for refinement, feel, and longevity.

---

Fluid, Heat, and Feel: The Often Overlooked Heart of Brake Performance

Brake fluid maintenance is one of the most underestimated aspects of brake care, yet it is central to refined, predictable braking. Brake fluid is hygroscopic—it absorbs moisture over time. As water content rises, the fluid’s boiling point drops, and under repeated hard stops or long descents, tiny vapor bubbles can form. This leads to a softer or spongy pedal, extended stopping distances, and a reduced safety margin in demanding conditions.

Manufacturers typically recommend replacing brake fluid every two to three years, but a more discerning approach may favor testing the fluid’s boiling point or moisture content during inspections, then tailoring the interval. A properly executed fluid flush—using the correct specification fluid for the vehicle and ensuring that fresh fluid reaches every corner of the system—restores hydraulic integrity and pedal consistency.

Fluid quality also shapes pedal feel. Consistent, properly bled fluid allows the brake pedal to communicate precisely what the tires and road surface are doing. This clarity is not just a comfort or performance luxury; it enables finer control in emergencies, better modulation on slippery surfaces, and reduced driver fatigue in stop‑and‑go traffic.

---

Five Exclusive Insights for Exceptionally Safe Brake Maintenance

These five insights are designed for owners who want to move past basic compliance and into a more curated, safety‑forward brake strategy.

1. Treat the First 500 Miles After Brake Service as a Critical Phase

The break‑in, or “bedding,” period following new pads and rotors is not a mere formality. Initial miles allow pad material to transfer evenly onto the rotor, creating a uniform friction layer that delivers stable, predictable braking. Gentle, progressive stops from moderate speeds—avoiding hard emergency‑style braking unless required—help the system settle without generating excessive heat spots.

Why it matters: Poorly managed break‑in can cause uneven pad deposits, leading to judder, vibration, or hot spots that prematurely compromise rotor life. Treating the first 500 miles with intention protects your investment and preserves that new‑brake smoothness.

2. Monitor Brake Performance Under Load and on Inclines, Not Just Around Town

Many drivers evaluate their brakes in familiar, flat, low‑speed environments, but true brake integrity is tested when the system is stressed. Pay attention to pedal feel, required effort, and any emerging noise when the vehicle is fully loaded, descending long hills, or repeatedly stopping from higher speeds.

Why it matters: Subtle weaknesses—such as marginal fluid, borderline pad material, or uneven rotor conditioning—often reveal themselves only under heat and load. Identifying small changes early gives you time to schedule service before they evolve into safety concerns.

3. Use Your Tire Wear Pattern as an Indirect Brake Health Indicator

Your tires silently record how your entire chassis, including the brakes, is behaving. Feathered edges, cupping, or uneven wear can suggest that the vehicle is not braking evenly or that the suspension and alignment are no longer allowing the brakes to do their job symmetrically.

Why it matters: While tire wear is not exclusively a brake issue, irregular patterns can prompt a more thorough brake and suspension inspection. Addressing both systems in harmony often yields not only safer stops but also a more composed, premium ride quality.

4. Consider Upgrading Hardware and Lubrication, Not Just Pads and Rotors

Many brake services focus narrowly on replacing friction components, but the “small” parts—shims, clips, guide pins, and lubricants—play a disproportionate role in refinement and longevity. Corroded pad clips, dry slide pins, or inferior lubricants can lead to uneven pad wear, dragging brakes, noise, and reduced efficiency.

Why it matters: Requesting high‑quality stainless hardware, correct high‑temperature brake lubricants, and careful cleaning of contact surfaces transforms a basic pad‑and‑rotor job into a premium service. The benefits show up in smoother application, quieter operation, and longer component life.

5. Align Brake Service Strategy with Vehicle Lifecycle and Future Plans

Brake maintenance decisions become more nuanced as a vehicle ages or nears a transition—whether you plan to keep it long‑term, hand it down, or sell it. For a vehicle you intend to keep for years, investing in higher-grade components, corrosion-resistant parts, and meticulous fluid service makes clear sense. For a car you may sell in the near future, the priority may be documented, high‑quality maintenance that demonstrates care to future buyers.

Why it matters: Aligning brake service with your ownership horizon prevents mismatches, such as over‑investing in performance components on a vehicle you plan to offload soon, or under‑servicing a car you expect to rely on for another decade. The most refined strategy is not simply the most expensive—it is the one that best matches your long‑term intentions.

---

Partnering with the Right Professionals

Even the most knowledgeable owner benefits from a strong relationship with a trusted brake specialist or service center. A premium approach prioritizes technicians who are willing to explain their findings, share measurements, and discuss options rather than defaulting to the most aggressive repair recommendation. Transparent inspection reports—often with photos, thickness readings, and fluid test results—bridge the gap between the shop’s expertise and the owner’s expectations.

Selecting a service partner with modern equipment, quality parts access, and a reputation for careful work pays dividends in confidence. Ask how they torque wheel fasteners, whether they resurface or replace rotors based on specification, and how they handle brake fluid flushing and bleeding. These details reveal whether the shop treats brake service as routine commodity work or as the safety‑critical discipline it truly is.

Over time, this partnership yields something subtle yet powerful: your technician becomes familiar with your vehicle’s history and your driving profile. That familiarity allows more precise recommendations, better long‑term planning, and fewer surprises.

---

Conclusion

Exceptional brake maintenance is quiet by design. There is no drama, no last‑minute rush to fix a squeal or pulsation, no uneasy second‑guessing when traffic suddenly compresses ahead. Instead, there is a composed assurance that every press of the pedal will deliver what you expect—linear response, controlled deceleration, and the ability to manage the unexpected.

By elevating brake care from a reactive chore to an intentional standard—supported by smart inspections, carefully chosen components, meticulous fluid management, and the five insights outlined above—you turn each journey into an exercise in controlled precision. For the refined driver, this is the true measure of luxury: not only how a car moves, but how confidently and gracefully it comes to a stop.

---

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brakes and Safety](https://www.nhtsa.gov/equipment/brakes) – Overview of brake system safety considerations and related regulations.

- [U.S. Department of Transportation – Brake Fluid Safety Brochure (PDF)](https://www.nhtsa.gov/sites/nhtsa.gov/files/brakefluid.pdf) – Explains brake fluid properties, moisture absorption, and maintenance recommendations.

- [AAA – Understanding Brake Maintenance](https://www.aaa.com/autorepair/articles/understanding-brake-maintenance) – Practical guidance on inspection intervals, components, and service considerations.

- [University of Nebraska–Lincoln – Brake System Basics (Transportation Safety)](https://transportation.unl.edu/safety/brake-system-basics) – Educational overview of brake components and how they function together.

- [Bosch Automotive – Brake System Components and Function](https://www.boschaftermarket.com/us/en/brake-systems/) – Technical information on modern brake system components and quality considerations from a major OEM supplier.

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.