There is a particular satisfaction in a vehicle that decelerates with quiet confidence—no shudder, no squeal, just composed, predictable control. For drivers who regard safety as a non‑negotiable luxury, brake maintenance is not a begrudging obligation; it is part of the art of owning a well‑kept machine. This guide explores a more refined approach to brake care, with five exclusive insights that help you move beyond “good enough” and into the realm of truly exceptional safety practices.

Why Maintenance Matters More Than Mileage

Many drivers wait for a mileage milestone or a warning light to think about their brakes. A more discerning approach looks at how the car feels and sounds long before any dashboard icon appears. Brake components are exposed to heat, moisture, and road contaminants every time you drive, and they wear in ways that depend heavily on your environment and habits—not just the odometer.

Short urban journeys, frequent downhill driving, or spirited highway use can age your braking system far faster than gentle suburban cruising. Moisture can infiltrate brake fluid and corrode internal components; road salt can attack lines, calipers, and backing plates; even your parking habits (for example, always leaving the car wet in a tight, poorly ventilated garage) can influence how quickly rotors rust. For the safety‑conscious owner, understanding these subtleties is the difference between reacting to problems and pre‑empting them elegantly.

Insight 1: Listen to the “Quiet” Indicators, Not Just the Loud Ones

Most drivers only react when the brakes become audibly or visibly troublesome: squeals, grinding, longer stopping distances. But the most refined brake care begins well before that.

Pay attention to the early, quiet indicators:

- A faint, intermittent chirp that disappears when you brake harder can be a wear indicator tab lightly touching the rotor—a polite request for inspection, not a crisis.

- A soft change in brake pedal “texture” (mushier or slightly longer travel) can signal moisture‑contaminated brake fluid or subtle air intrusion.

- A barely perceptible pull to one side under gentle braking may indicate an early sticking caliper or uneven pad wear long before it becomes dramatic.

- A slight pulsation only at certain speeds under light braking can be an early sign of rotor thickness variation, not yet severe enough to cause obvious vibration.

Treat these quiet clues as an invitation to schedule a professional inspection rather than waiting for a jarring symptom. The reward is a braking system that remains consistently poised, instead of oscillating between “fine” and “urgent repair.”

Insight 2: Elevate Brake Fluid from Afterthought to Priority

Brake fluid is often overshadowed by pads and rotors, yet it is the lifeblood of your braking system. Over time, it absorbs moisture from the atmosphere—a process called hygroscopy—which lowers its boiling point and invites internal corrosion. The result can be a spongy pedal during hard stops and unseen damage to calipers, ABS modules, and lines.

A refined maintenance approach:

- Treat brake fluid service as a scheduled event, not a reaction to fading performance. Many manufacturers suggest every 2–3 years; drivers in humid or coastal climates may benefit from the shorter end of that range.

- Ask your technician whether they measure fluid boiling point or moisture content; this is a more precise gauge of condition than color alone.

- Insist on a proper flush, not merely a partial “top‑off.” Old fluid lingering in lines and calipers defeats the purpose of fresh fluid in the reservoir.

- If your vehicle has high‑performance or heavy‑duty use (towing, mountain driving, track days), discuss an appropriate fluid specification with your service professional.

Prioritizing brake fluid is a subtle but powerful way to protect both performance and longevity—an internal assurance that matches the external polish of a well‑maintained vehicle.

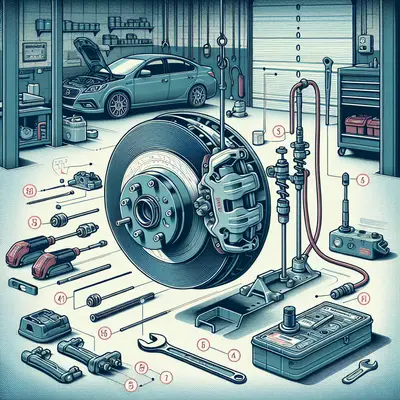

Insight 3: Treat Calipers and Hardware as Critical, Not Peripheral

Pads and rotors tend to get all the attention, but calipers and their hardware quietly determine how evenly and reliably those components perform. A premium brake experience depends on calipers that move freely and hardware that remains clean, lubricated, and corrosion‑free.

Elevated practices include:

- Ensuring that each brake service includes cleaning and lubricating slide pins with the correct high‑temperature synthetic grease, not generic lubricants that can swell rubber or burn off.

- Replacing pad hardware (shims, clips, springs) as needed, rather than reusing tired, corroded pieces for “economy.” Fresh hardware helps pads retract smoothly, reducing noise, uneven wear, and drag.

- Asking for evaluation of caliper piston boots and dust seals—small rubber components that, when compromised, can invite moisture and contamination into caliper internals.

- In regions with harsh winters or salted roads, having your technician inspect calipers and brackets carefully for corrosion that could cause binding or misalignment over time.

By elevating calipers and hardware to the same level of importance as pads and rotors, you safeguard the uniformity of braking feel: the kind of consistent, linear response that discriminating drivers immediately recognize and value.

Insight 4: Align Driving Style with Your Brake System’s Design

Modern braking systems are engineered to work in concert with traction control, stability control, and in many cases, sophisticated driver‑assistance features. How you use your brakes can either complement that engineering or work against it.

A refined driver:

- Uses progressive, firm initial pedal application rather than timid “nibbling” at the brakes, which can cause unnecessary heat and glazing of pads.

- Anticipates traffic patterns to avoid repeated hard stops from high speeds—especially with heavier vehicles or those frequently carrying passengers and cargo.

- Respects break‑in (bedding) procedures after new pads and rotors are installed, allowing friction surfaces to mate properly. Done correctly, this reduces the risk of uneven pad transfer and future pulsation.

- Understands that frequent use of downhill engine braking (downshifting) helps keep brake temperatures moderated, preserving pad integrity and rotor condition.

When your driving style aligns with how your brake system is intended to operate, you not only extend the life of components but also keep their performance closer to “as‑engineered”—sharp, predictable, and reassuringly calm.

Insight 5: Make the Annual Brake Inspection a Non‑Negotiable Ritual

For a driver who values quiet excellence over drama, a structured inspection routine is essential. Not merely a quick visual glance, but a methodical, documented assessment at least annually—or more often if your mileage or usage is demanding.

A high‑caliber brake inspection should include:

- Measuring pad thickness at each wheel and noting patterns of uneven wear.

- Inspecting rotors for thickness variation, runout (wobble), scoring, and heat spots, not just obvious grooves.

- Examining brake lines—both rigid and flexible—for rust, cracking, bulging, or chafing.

- Checking the master cylinder, booster, and reservoir for leaks, contamination, or improper fluid level.

- Evaluating the parking brake mechanism (cable‑operated or electronic) for proper engagement and release.

- For vehicles with advanced driver‑assistance systems (ADAS), ensuring there are no brake‑related fault codes and that ABS operation appears normal under controlled test conditions.

Treat this inspection as part of your vehicle’s annual wellness exam, and request a record of measurements and findings. Over time, this creates a personal “brake dossier” for your car—valuable for both safety and resale, and deeply satisfying for the owner who appreciates a documented history of conscientious care.

Conclusion

A truly refined driving experience is not defined solely by acceleration or luxury finishes; it is measured just as much by how gracefully a vehicle slows and stops. By listening to early signals, elevating brake fluid care, paying due respect to calipers and hardware, harmonizing your driving style with your brake system’s design, and committing to a rigorous annual inspection, you build a foundation of quiet, unshakeable confidence.

In a world where many view brake service as a reluctant expense, you can choose to treat it as an investment in control, composure, and peace of mind. The result is not just safer motoring, but a driving experience that feels meticulously considered—down to the last, elegant moment of deceleration.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brakes and Safety](https://www.nhtsa.gov/equipment/brakes) - Federal guidance on brake safety, performance, and defect information

- [U.S. Department of Transportation – Brake Fluid and Hydraulic Systems](https://www.transportation.gov/mission/safety) - Technical and safety context for hydraulic brake systems and maintenance considerations

- [University of California, Berkeley – Tech Transfer: Brake System Basics](https://www.techtransfer.berkeley.edu/brake-systems-and-vehicle-dynamics) - Educational overview of brake system components and their interaction with vehicle dynamics

- [AAA – Brake System Maintenance Recommendations](https://exchange.aaa.com/automotive/maintenance/brake-system/) - Consumer‑focused advice on inspection intervals, fluid changes, and common wear patterns

- [Bosch Mobility – Braking Systems Technology](https://www.bosch-mobility.com/en/solutions/passenger-cars-and-light-commercial-vehicles/braking-systems/) - Manufacturer insight into modern braking technologies and component design

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Maintenance.