Behind every composed stop is a precisely coordinated mechanical ballet. For the discerning driver, brakes are not merely hardware; they are the final expression of a vehicle’s engineering integrity and a guardian of personal safety. Understanding how your brake system truly works—and how to care for it with intention—transforms routine maintenance into a measured, confidence-building practice.

The Architecture of a Modern Brake System

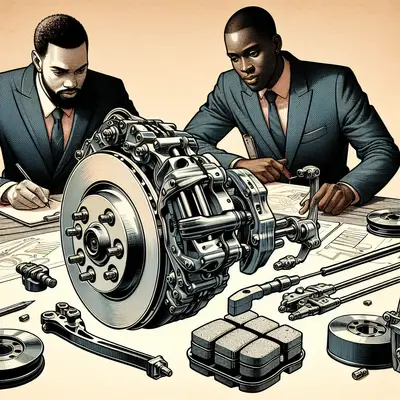

At its core, a modern hydraulic brake system converts the subtle pressure of your foot into powerful clamping force at each wheel. When you press the pedal, a pushrod actuates the master cylinder, pressurizing brake fluid that travels through steel lines and flexible hoses to calipers (or wheel cylinders in drum systems). The calipers squeeze brake pads against rotating discs (rotors), converting kinetic energy into heat through friction, and slowing the vehicle.

Contemporary systems weave in advanced layers of control. Anti-lock braking systems (ABS) prevent wheel lockup by modulating pressure in milliseconds, maintaining steerability on slippery surfaces. Electronic brake-force distribution (EBD) refines how pressure is apportioned between front and rear, enhancing stability during varied load conditions. In more advanced platforms, brake-by-wire systems and integrated stability control use sensors and control units to fine-tune braking at each wheel. When these components are healthy and correctly calibrated, the result is a firm, predictable pedal and smooth, drama-free deceleration.

The Often-Ignored Foundation: Brake Fluid as a Precision Medium

Brake fluid is more than a consumable—it's the invisible medium that determines how faithfully your input at the pedal translates into stopping power. Glycol-based fluids (DOT 3, 4, and some DOT 5.1) are hygroscopic, meaning they absorb moisture over time, even through microscopic permeation in hoses and seals. As water content rises, the boiling point of the fluid drops; under hard braking, this can produce vapor bubbles that compress, leading to a spongy pedal or, in severe cases, temporary loss of braking.

What sets refined brake care apart is proactive fluid management. Rather than waiting for obvious symptoms, many experts recommend testing brake fluid periodically for moisture content and replacing it according to the manufacturer’s interval—or sooner if the vehicle is subjected to heavy braking, mountain driving, or track use. The color of fluid in the reservoir is not a definitive indicator; clear or amber fluid can still be compromised. An intentional fluid service, properly bled to remove air, can transform pedal feel from vague to precise and restore the system’s thermal resilience during emergency stops.

Beyond “Pads and Rotors”: How Components Age Together

Most drivers focus on pads and rotors, but a brake system ages as an ecosystem. Pads wear down over time, and their friction compound gradually loses efficiency as it heat cycles. Rotors not only thin with wear but can develop hard spots, glazing, or subtle surface variations that lead to shudder under braking. Caliper slide pins can dry out, causing uneven pad wear, and rubber hoses can swell internally, subtly delaying pressure buildup and release.

Premium maintenance respects this interdependence. Instead of simply installing new pads on deeply grooved rotors or ignoring sticky caliper hardware, a meticulous approach evaluates pad wear patterns, rotor thickness and runout, caliper operation, and hose condition as a whole. Matching pad compound to driving style—touring, city-heavy, or performance-oriented—also matters: an aggressive pad may stop harder but create more noise and dust, while a comfort-focused pad emphasizes quiet and smoothness. The result of this holistic method is consistent, linear braking rather than a patchwork of mismatched components.

Five Exclusive Insights for the Safety-Conscious Driver

For owners who view brake safety as non-negotiable, subtle details can make a meaningful difference. These five insights move beyond standard advice and into the realm of refined practice:

**Pedal Feel is a Diagnostic, Not Just a Sensation**

A firm, predictable pedal that remains consistent from the first stop of the day to the last is a hallmark of a healthy system. A pedal that gradually sinks at a stoplight can suggest internal leakage in the master cylinder. A spongy pedal that improves when pumped may indicate air in the lines. Paying attention to *how* the pedal responds over a week of driving can reveal issues long before a warning light appears.

**Brake Noise is a Language, Not a Nuisance**

Occasional light squeaks in damp conditions may be benign surface rust being cleaned off the rotors. However, persistent high-pitched squeals often signal that wear indicators on pads are contacting the rotor, warning of low material. A grinding sound typically means the friction lining has worn away entirely and metal is contacting metal, risking rotor damage. A refined driver treats new or changing sounds as actionable clues, not background irritations.

**Parking Habits Quietly Shape Brake Longevity**

Regularly parking on steep inclines and relying solely on the transmission’s parking pawl (without a parking brake) can stress driveline components and, in some cases, influence how load is distributed when you release the pedal and move off. Using the parking brake habitually—especially on vehicles with rear drum or drum-in-hat parking brakes—helps keep those mechanisms exercised and less prone to seizing. In climates with road salt, this simple routine can prolong the life and reliability of rear brake components.

**Wheel and Tire Choices Subtly Affect Brake Performance**

Larger-diameter wheels with very open spoke designs can improve brake cooling by allowing more airflow, potentially reducing fade on long descents. Conversely, extremely heavy wheels increase unsprung and rotating mass, asking more of the brake system to slow them. Tire grip is equally critical: the best brakes cannot overcome poor traction. High-quality tires with appropriate load and speed ratings allow the ABS and stability systems to work to their potential, translating brake force into controllable deceleration rather than noise and vibration.

**A Gentle “Brake Bedding” Ritual After Service Pays Dividends**

Following a brake job, properly bedding new pads and rotors is a refined step that many overlook. Moderate, repeated stops from progressively higher speeds—without coming to a complete stop and holding the pedal hard—help transfer an even layer of pad material onto the rotor face. This conditioning can reduce judder, enhance initial bite, and promote quieter operation over the life of the pads. It is a subtle, deliberate process that separates routine replacement from truly optimized braking.

Reading the Road: How Conditions Change Brake Behavior

Brake performance is inseparable from environment. In heavy rain, water film can momentarily reduce friction between pad and rotor; applying the brakes lightly in a safe moment can help clear the rotors and restore bite. On steep mountain descents, prolonged braking can overheat pads and fluid; the more sophisticated strategy is to downshift appropriately and let engine braking share the workload, preserving thermal capacity for sudden stops.

Cold weather adds its own nuances. Surface rust forming overnight on rotors in humid or salty conditions can cause a rough feel or light scraping during the first few stops, which often subsides quickly. In extreme cold, brake fluid viscosity can increase slightly, and rubber components may stiffen, affecting feel at the pedal until the system warms. For those who tow or carry heavy loads, understanding that braking distances will increase—and planning following distance accordingly—shows an appreciation for the system’s real-world limits, not just its theoretical capability.

When Technology Intervenes: Understanding ABS and Assist Systems

When ABS engages, the pulsing pedal and vibration can surprise unprepared drivers. Rather than easing off, the correct response in an emergency is to maintain firm pressure and steer around the hazard; the system is rapidly modulating pressure to prevent lockup. Brake assist systems monitor pedal speed and force, boosting pressure when a panic stop is detected—even if the driver does not fully depress the pedal. Electronic stability control may apply brakes at individual wheels to realign the vehicle during abrupt maneuvers.

For the sophisticated owner, familiarity with these interventions builds trust rather than anxiety. A controlled test in an empty, safe area—accelerating to moderate speed and executing a firm stop—can help you recognize the sensations of ABS and confirm that the system is working as intended. Understanding the interplay between software and hardware ensures that, when intervention is needed, it feels like a well-rehearsed collaboration rather than an unexpected intrusion.

Conclusion

A brake system is at its best when it is almost invisible—responsive, silent, and utterly predictable. Achieving that level of composure is not a matter of chance; it is the outcome of informed choices, attentive listening to small changes, and respect for the engineering at work beneath the pedal. For the driver who values both refinement and safety, elevating brake care from occasional repairs to deliberate stewardship turns every stop into a quiet affirmation of control.

Sources

- [National Highway Traffic Safety Administration (NHTSA) – Brake Safety](https://www.nhtsa.gov/equipment/brakes) - Federal guidance on brake system safety, recalls, and performance expectations

- [Car and Driver – How Your Car’s Brakes Work](https://www.caranddriver.com/features/a15134430/how-your-cars-brakes-work-feature) - Clear technical explanation of modern hydraulic braking systems and components

- [Federal Motor Carrier Safety Administration (FMCSA) – Brake Systems](https://www.fmcsa.dot.gov/brake-systems) - Regulatory perspective on brake performance and inspection principles

- [University of Nebraska–Lincoln – Brake System Basics](https://transportation.unl.edu/brake-systems) - Educational overview of brake components, function, and maintenance considerations

- [Bosch Mobility – Brake System Technologies](https://www.bosch-mobility.com/en/solutions/passenger-cars-and-light-commercial-vehicles/brake-systems) - Manufacturer insights into ABS, EBD, and modern brake control innovations

Key Takeaway

The most important thing to remember from this article is that this information can change how you think about Brake Systems.